Medical automatic cleaning machine

A technology of automatic cleaning machine and outer casing, which is applied in the direction of cleaning method using liquid, using re-radiation, cleaning method and utensils, etc., which can solve the problems of different shapes and sizes of medical equipment and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

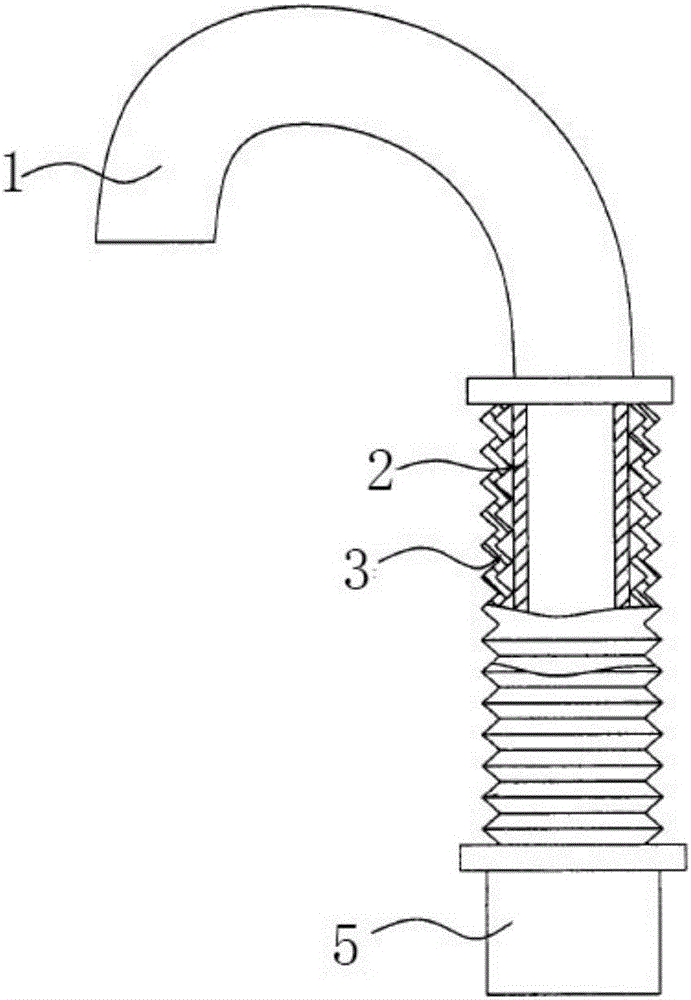

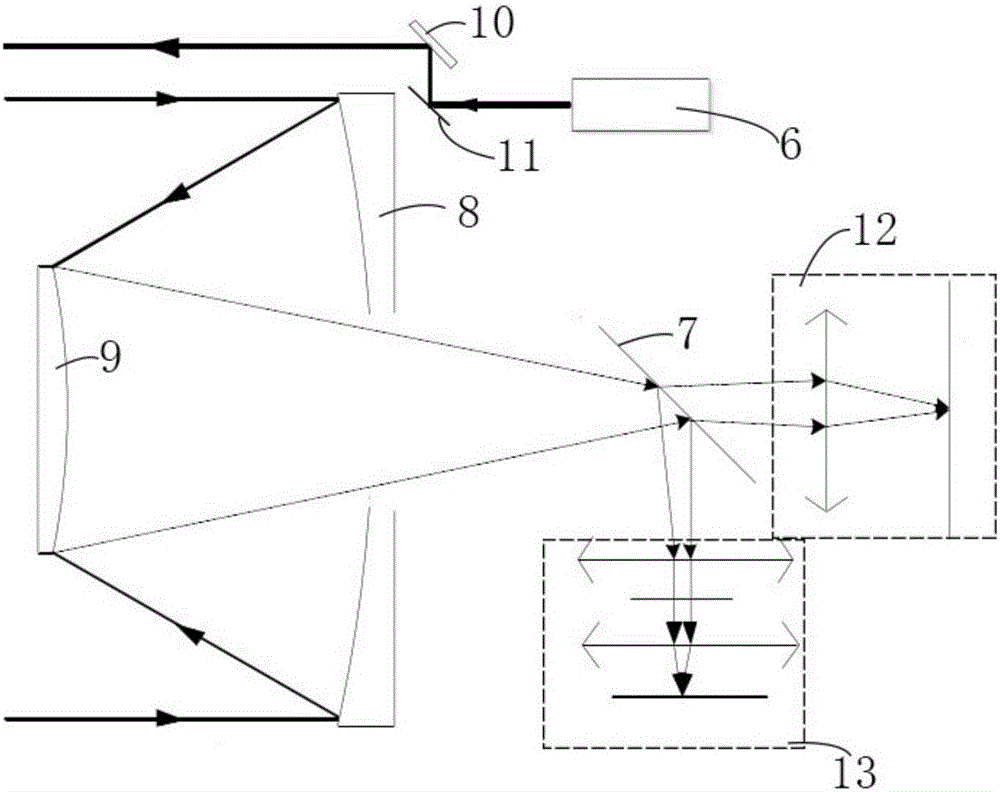

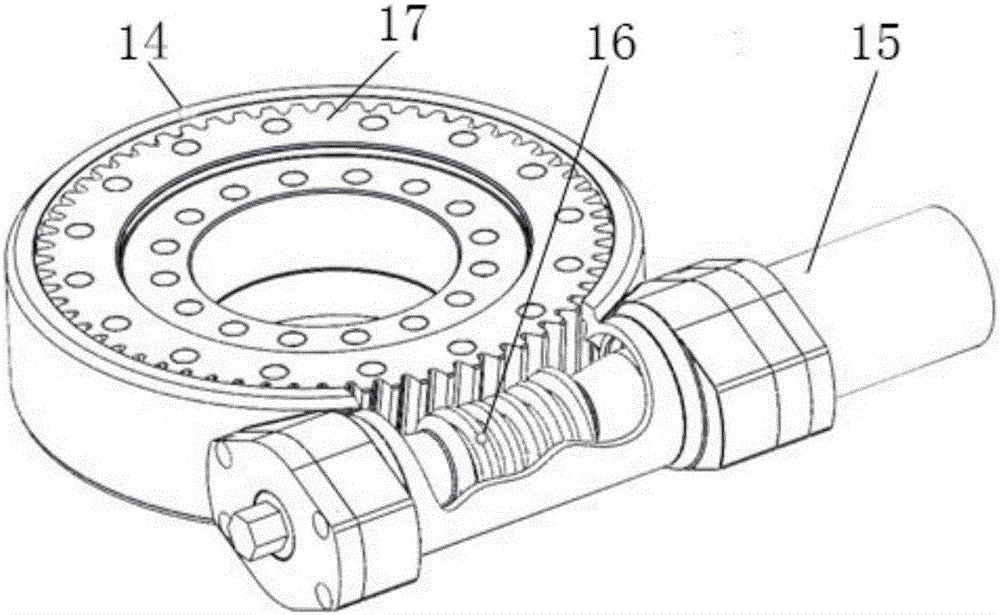

[0038] The device of the present invention comprises a water gun body 1, a total water gun base 5 and a plurality of detachable sub-water gun bases, such as figure 1 As shown, the water gun body 1 is detachably arranged on the main water gun base 5, and the sub-water gun bases are installed at different positions around the washbasin, which is convenient for users to use. One end of the water gun body 1 is a water outlet, and the other end is a water inlet. The water inlet is connected with a water inlet pipe 2 and a flexible pipe 3 wrapping the water inlet pipe 2. The water inlet pipe 2 and the flexible pipe 3 extend to the inside of the main water gun base 5 and are connected with a solenoid valve. The solenoid valve controls The connection of the water inlet pipe 2. One side of the total water gun base 5 is provided with a sensing device, and the sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 an...

Embodiment 2

[0075] The device of the present invention comprises a water gun body 1, a total water gun base 5 and a plurality of detachable sub-water gun bases, such as figure 1 As shown, the water gun body 1 is detachably arranged on the main water gun base 5, and the sub-water gun bases are installed at different positions around the washbasin, which is convenient for users to use. One end of the water gun body 1 is a water outlet, and the other end is a water inlet. The water inlet is connected with a water inlet pipe 2 and a flexible pipe 3 wrapping the water inlet pipe 2. The water inlet pipe 2 and the flexible pipe 3 extend to the inside of the main water gun base 5 and are connected with a solenoid valve. The solenoid valve controls The connection of the water inlet pipe 2. One side of the total water gun base 5 is provided with a sensing device, and the sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 an...

Embodiment 3

[0112] The device of the present invention comprises a water gun body 1, a total water gun base 5 and a plurality of detachable sub-water gun bases, such as figure 1 As shown, the water gun body 1 is detachably arranged on the main water gun base 5, and the sub-water gun bases are installed at different positions around the washbasin, which is convenient for users to use. One end of the water gun body 1 is a water outlet, and the other end is a water inlet. The water inlet is connected with a water inlet pipe 2 and a flexible pipe 3 wrapping the water inlet pipe 2. The water inlet pipe 2 and the flexible pipe 3 extend to the inside of the main water gun base 5 and are connected with a solenoid valve. The solenoid valve controls The connection of the water inlet pipe 2. One side of the total water gun base 5 is provided with a sensing device, and the sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com