An adjustment method for an intelligent automatic speed regulation system of a mill

An automatic speed regulation and intelligent speed regulation technology, which is applied in grain processing and other fields, can solve problems such as high labor intensity, achieve strong anti-interference ability, obvious measurement signal characteristics, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

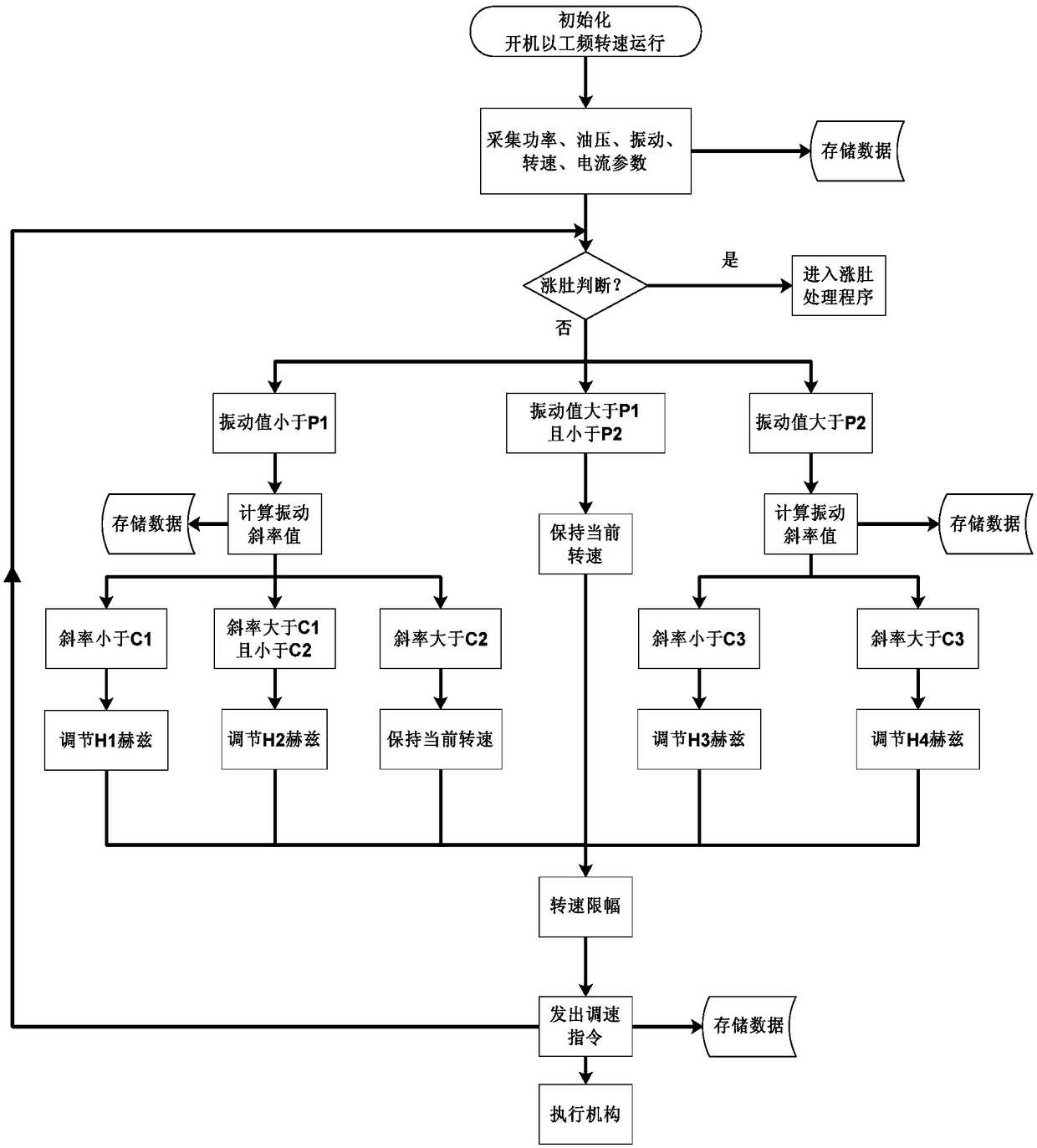

Method used

Image

Examples

Embodiment 1

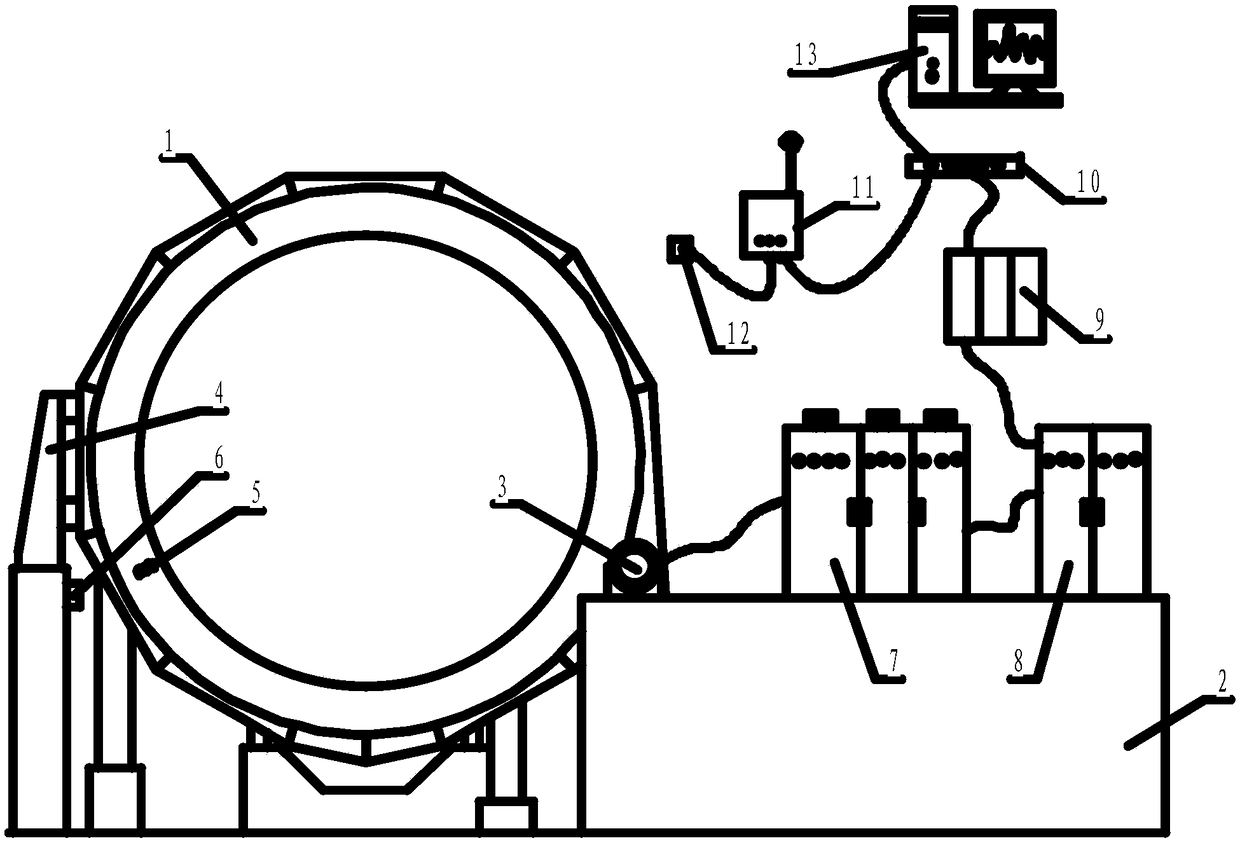

[0046] A mill 1 is arranged on one side of the base 2, a stand 4 is arranged under the mill 1, a motor 3 is arranged on one side above the base 2, the motor 3 drives the mill 1 to rotate, and a wireless vibration sensor 5 is arranged on the mill 1, so A trigger 6 is set on the stand 4, a governor 7 is set between the motor 3 and the low-voltage control cabinet 8, a data acquisition module 9 is set between the low-voltage control cabinet 8 and the switch 10, and the switch 10 is set in the wireless vibration signal processing and intelligent Between the speed regulation strategy system 13 and the wireless vibration signal receiver 11, an AC power supply 12 is arranged on one side of the wireless vibration signal receiver 11, a motor 3, a governor 7, a low-voltage control cabinet 8, a data acquisition module 9, a switch 10, a wireless Vibration signal receiver 11, AC power supply 12, wireless vibration signal processing and intelligent speed regulation strategy system 13 are prov...

Embodiment 2

[0057] The parameter values used in the wireless vibration signal processing and intelligent speed regulation strategy system 13 are all obtained from the analysis and summary of the historical operation data of the mill 1. , setting and fine-tuning the parameter values, the wireless vibration signal processing and intelligent speed regulation strategy system 13 is developed with a special parameter setting interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com