Cracking gasification catalytic composition, preparation method thereof, and cracking gasification method of petroleum hydrocarbons

A composition and compound technology, applied in chemical instruments and methods, physical/chemical process catalysts, cracking, etc., can solve the problems of potassium loss, low cracking activity, high gasification temperature, etc., and achieve improved gasoline yield and high catalytic The effects of cracking activity and low gasification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the preparation method of the above-mentioned mesoporous active material, the room temperature is usually 5-40°C, for example, 5°C, 10°C, 15°C, 20°C, 25°C, 30°C or 35°C.

[0048]In addition, optionally, the preparation method of the above-mentioned active mesoporous material may also include the step of roasting the dried product, and the conditions of the roasting generally include that the roasting temperature may be 500-700° C., and the roasting time may be 1-4 hours. .

[0049] In the preparation method of the above-mentioned mesoporous active material, the type of phosphorus source described in step (4) can be a conventional choice in the art, for example, can be selected from ammonium phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate and phosphoric acid one or more of .

[0050] In the preparation method of the above-mentioned mesoporous active material, the compound of the metal M in step (4) may be any water-soluble compound.

[0051] ...

Embodiment approach

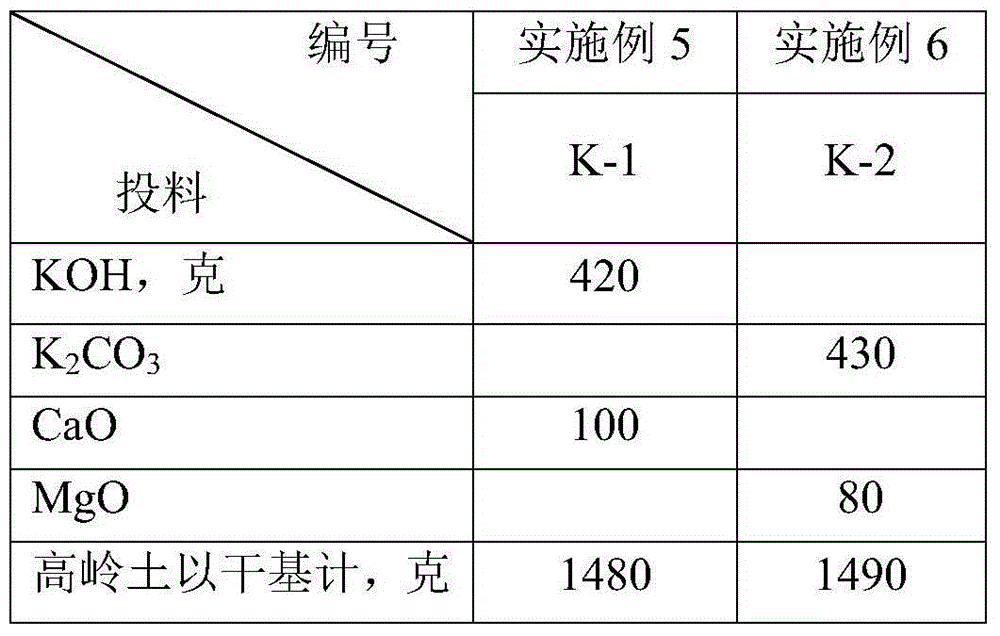

[0096] According to the preparation method of the above-mentioned catalytic composition provided by the present invention, after mixing the active mesoporous material, gasification active component, clay, and heat-resistant inorganic oxide matrix, perform beating, spray drying and roasting according to conventional methods in the art That's it. In a preferred embodiment of the present invention, the preparation method of the above-mentioned catalytic composition comprises the following steps:

[0097] (1) Neutralize the aluminum source and alkali solution at room temperature to 85°C to form a gel, and control the pH value of the gel to be 7-11 to obtain a gelled slurry; according to SiO 2 :Al 2 o 3 =1: (1.0-7.5) weight ratio, adding a silicon source to the gelling slurry, aging at room temperature to 90° C. for 1-5 hours, to obtain the first solid precipitate; the first solid precipitate Contact treatment with ammonium salt or acid solution, filter to obtain a second solid ...

Embodiment 1

[0126] (1) With a concentration of 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 solution and concentration of 102gAl 2 o 3 / L, NaAlO with a caustic ratio of 2.5 2 The solution is the raw material for the reaction. It adopts the method of co-flow gelation, and mixes it under vigorous stirring to form a gel. The temperature of the system is controlled at 50°C, the pH value of the system is 9.0, and it is collected and measured to form a gelatinous liquid;

[0127] (2) According to SiO under stirring 2 :Al 2 o 3 = 1: 1.94 weight ratio, add SiO with a concentration of 60g to the gelling slurry 2 / L of water glass, warming up to 60 ℃ for aging for 3 hours, to obtain the first solid precipitate; (3) the first solid precipitate according to its precipitate dry basis: ammonium salt: H 2 Add NH at a weight ratio of O=1:0.5:12 4 Cl and deionized water, carry out ion exchange to remove sodium ion to precipitate at 60 ℃, exchange repeats once, each 0.5 hour, to sodium oxide content is lower t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com