A kind of catalytic cracking catalyst and its preparation method and application

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as poor coke selectivity, achieve low coke selectivity, high catalytic cracking activity, and increase the content of mesopores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

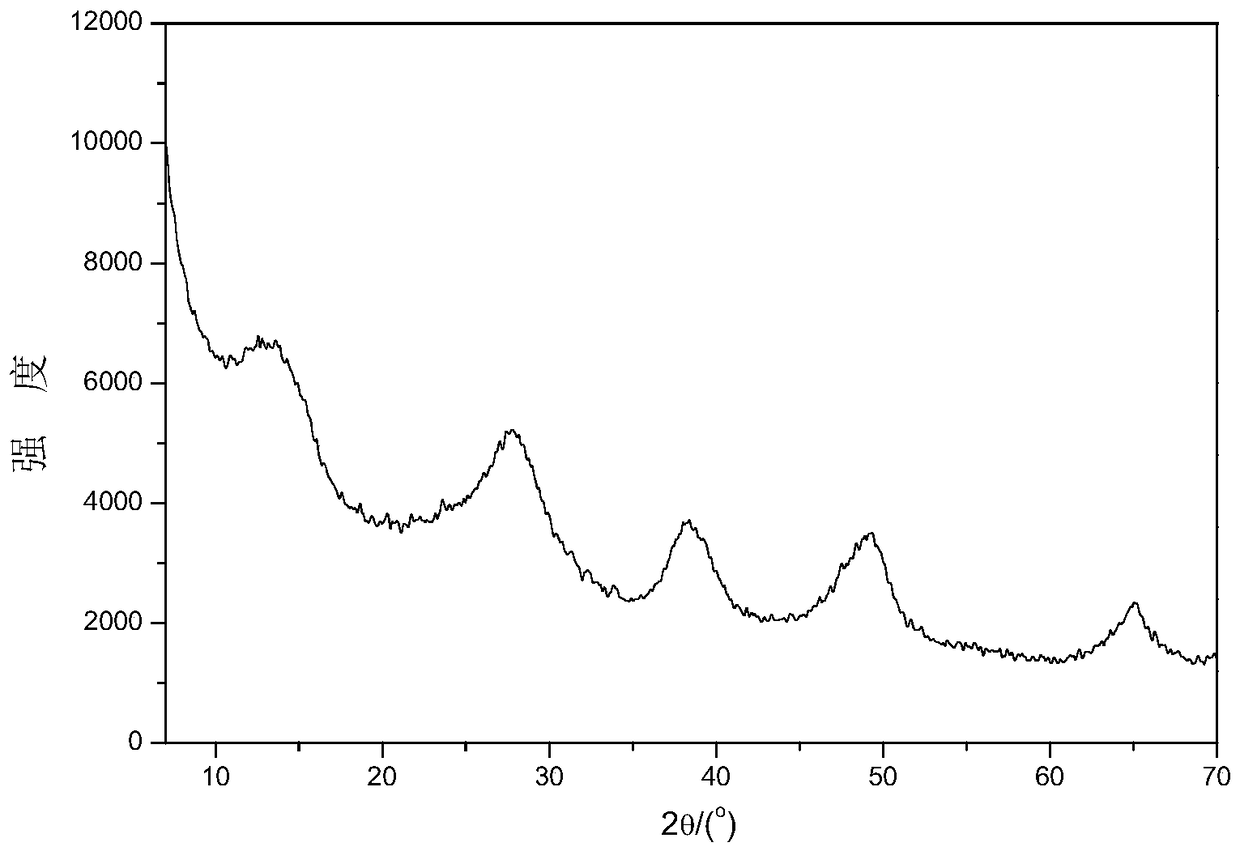

Image

Examples

preparation example Construction

[0060] The preparation method of the catalytic cracking catalyst provided by the invention comprises mixing and beating the above-mentioned cracking active component, mesoporous active material, clay and binder, and then performing spray drying, washing, filtering and drying in sequence.

[0061] According to the preparation method of catalytic cracking catalyst provided by the present invention, the cracking active component, mesoporous active material, clay and binder are mixed and beaten, and the subsequent spray drying, washing, filtering and drying are the implementation methods of these processes All can be implemented by conventional methods, and their specific implementation methods are described in detail in CN1916166A, CN1098130A, CN1362472A, CN1727442A, CN1132898C and CN1727445A, which are incorporated into the present invention for reference. In addition, generally, after the spray-drying and before washing, the preparation method of the catalytic cracking catalyst ...

preparation example 1

[0077] This preparation example is used to illustrate the phosphorus- and metal-modified mesoporous silica-alumina material provided by the present invention and its preparation method.

[0078] (1) First, the concentration is 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 Put the solution in a beaker, add ammonia water with a concentration of 25wt.% under stirring until the system pH=10.0, keep the gelling temperature at 40°C, collect and measure it into a glue liquid; (2) under stirring conditions, according to SiO 2 :Al 2 o 3 = 1:3 weight ratio Adding concentration of 60g SiO to the gelling slurry 2 / L of water glass, warming up to 80° C. and aging for 1 hour, to obtain the first solid precipitate; (3) the first solid precipitate according to its precipitate dry basis: HCl: H 2 The weight ratio of O=1:0.08:12 was exchanged at 50°C for 30 minutes, filtered and washed with water to obtain the second solid precipitate with a sodium oxide content lower than 0.3%; (4) the second solid pre...

preparation example 2

[0081] This preparation example is used to illustrate the phosphorus- and metal-modified mesoporous silica-alumina material provided by the present invention and its preparation method.

[0082] (1) With a concentration of 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 solution and concentration of 102gAl 2 o 3 / L, NaAlO with a caustic ratio of 2.5 2 The solution is the raw material for the reaction, and it adopts the method of co-current gelation, and mixes it under vigorous stirring to form a gel. The temperature of the system is controlled at 40 ° C, the pH of the system is 10.5, and it is collected and measured into a gelatinous liquid; 2 :Al 2 o 3 = 1:1.2 weight ratio, add SiO at a concentration of 100g to the gelling slurry 2 / L of water glass, warming up to 70°C for aging for 2 hours, to obtain the first solid precipitate; (3) the first solid precipitate according to its precipitate dry basis: HCl: H 2 The weight ratio of O=1:0.08:15 was exchanged at 60°C for 30 minutes, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com