Supramolecular polymer nanofiltration membrane and preparation method thereof

A technology of supramolecular polymers and nanofiltration membranes, applied in the field of nanofiltration membranes, can solve problems such as no related research on membrane separation materials, and achieve the effects of increased control means, fewer assembly layers, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The ultrafiltration membrane used in this embodiment is an alkali-modified polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of 50,000. Supramolecular polymer made of Zn 2+ Coordination of ions with bischelidinic acid ligand.

[0030] The assembly is carried out in a porcelain container with a porous support with a diameter of 10 cm. Place the ultrafiltration membrane with the membrane side up and the edges fixed, place it in a container, and assemble it according to the following steps:

[0031] 1) Prepare a 0.2% polyallylammonium chloride solution by mass percentage, add NaCl, the NaCl concentration is 0.5M, and the pH is adjusted to 2.5.

[0032] 2) Prepare 5mmol / L zinc ion solution and dichelioleic acid solution respectively, adjust the pH to 5.4 with buffer solution, press Zn 2+ : L 2 EO 4 The two solutions are mixed at a ratio of 1:1, and the supramolecular polymer is obtained after being placed, ready to be assembled.

[0033] 3) Add polyallyl a...

Embodiment 2

[0043] The ultrafiltration membrane used in this embodiment is a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 30,000. Supramolecular polymer made of Fe 3+ Coordination of ions with bischelidinic acid ligand.

[0044] The assembly is carried out in a porcelain container with a porous support with a diameter of 10 cm. Place the ultrafiltration membrane with the membrane side up and the edges fixed, place it in a container, and assemble it according to the following steps:

[0045] 1) Prepare a polyallylammonium chloride solution with a concentration of 0.3% by mass, add NaCl, the concentration of NaCl is 0.5M, and adjust the pH to 3.0.

[0046] 2) Prepare 5mmol / L iron ion solution and bischelioleic acid solution respectively, adjust pH to 5.4 with buffer solution, press Fe 3+ : L 2 EO 4 The two solutions are mixed at a ratio of 1:2, and the supramolecular polymer is obtained after being placed.

[0047] 3) Add polyallyl ammonium chloride solution to the ...

Embodiment 3

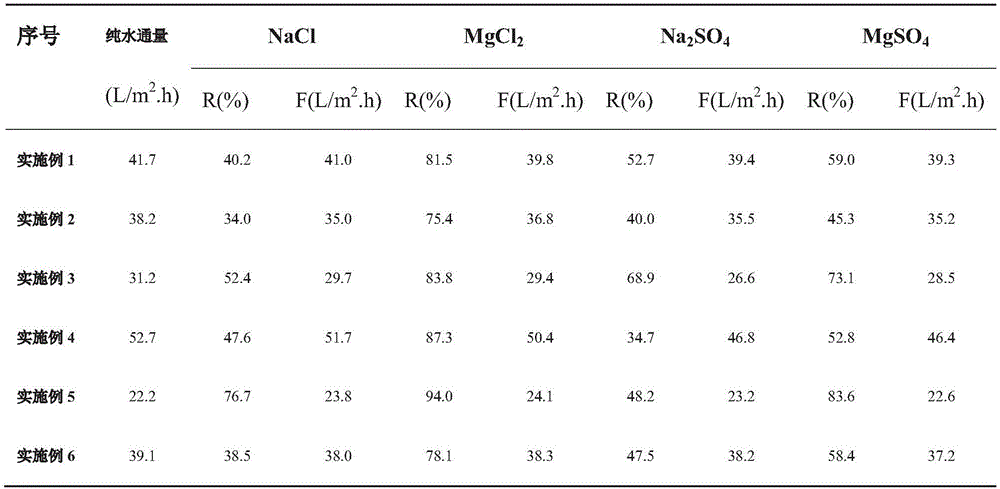

[0057] According to the conditions of Example 1, press Zn 2+ : L 2 EO 4 Supramolecular polymer was prepared by coordination with a ratio of 1:2, and the nanofiltration membrane was obtained after two rounds of assembly. The separation performance of the membrane in Example 3 is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com