Cadmium telluride quantum dot/titanium dioxide composite material and application thereof

A technology of cadmium telluride quantum dots and titanium dioxide, applied in other chemical processes, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low utilization rate of sunlight, improve photocatalytic activity, expand application range, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] (1) The sodium tellurium hydride solution can be prepared by the following steps: according to the ratio of using 2mL deionized water and 0.6g tellurium powder for every 1.2g sodium borohydride, sodium borohydride is mixed with deionized water and tellurium powder, And heating in a water bath at a water bath temperature of 80° C. until the mixed solution becomes colorless and transparent, thereby preparing a sodium telluride hydride solution.

[0023] (2) After the above 180°C insulation for 48 hours, cool to room temperature first, then clean the obtained solid precipitate (preferably wash with water and then use ethanol to clean) and dry (preferably at 80°C drying), so as to obtain a clean and dry cadmium telluride quantum dot / titanium dioxide composite material.

[0024] Further, compared with the use of simple titanium dioxide as photocatalyst, the cadmium telluride quantum dot / titanium dioxide composite material provided by the present invention is obtained through...

Embodiment 1

[0027] A cadmium telluride quantum dot / titanium dioxide composite material is prepared by the following steps:

[0028] Step A: Purge the 50mL Erlenmeyer flask with nitrogen for 10 minutes, then weigh 1.2g of sodium borohydride and place it in the Erlenmeyer flask, then add 2mL of deionized water and 0.6g of tellurium powder, and set the temperature of the water bath at 80°C Heating in a water bath until the mixed solution becomes colorless and transparent, that is, a sodium telluride hydride solution is obtained.

[0029] Step B, under nitrogen protection environment, dissolve 0.35g cadmium chloride pentahydrate in 300mL deionized water, then add thioglycolic acid dropwise according to the molar ratio of cadmium chloride pentahydrate: thioglycolic acid=1:0.2~5, and use The NaOH solution of 1mol / L adjusts the pH value of mixed solution to alkaline, then according to cadmium chloride pentahydrate: the mol ratio of sodium telluride hydride=1:0.1~1 fast adds the sodium telluride ...

Embodiment 2

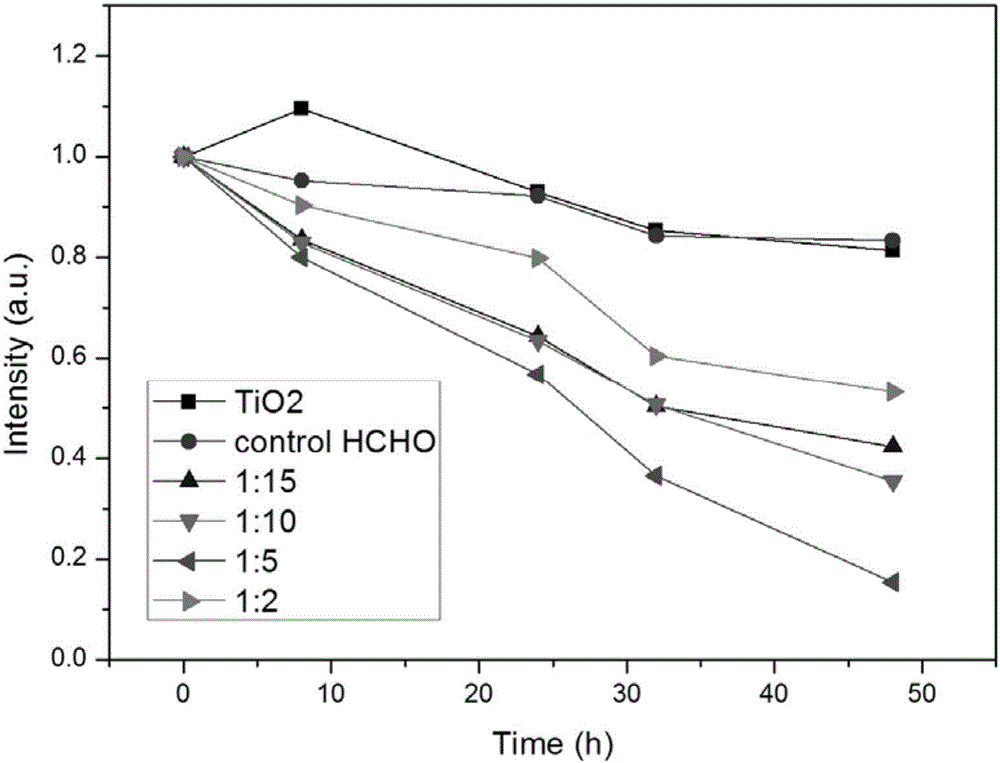

[0032] Respectively with titanium isopropoxide: the volume ratio of cadmium telluride quantum dot solution=1:2, 1:5, 1:10, 1:15, and according to the preparation step in the embodiment of the present invention 1, titanium isopropoxide is obtained The cadmium telluride quantum dot / titanium dioxide composite material whose volume ratio to the cadmium telluride quantum dot solution is 1:2, 1:5, 1:10, 1:15 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com