System and method for controlling odor and smoke in livestock and poultry farms

A technology for farms and odor, applied in the field of pollution control, can solve the problems of losing deodorization effect, reducing deodorization effect, affecting microbial growth and reproduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

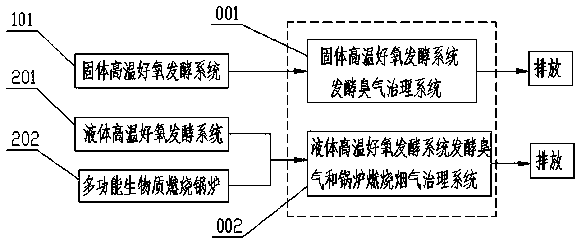

[0095] like figure 1 As shown, a livestock and poultry farm odor and flue gas treatment system includes a solid high-temperature aerobic fermentation system fermentation odor treatment system 001 and a liquid high-temperature aerobic fermentation system fermentation odor and boiler combustion flue gas treatment system 002.

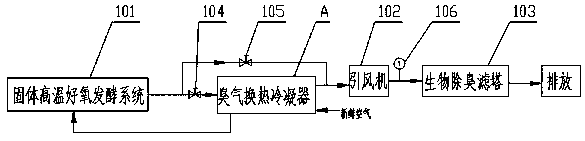

[0096] Solid high temperature aerobic fermentation system Fermentation odor control system 001, such as figure 2 As shown, the solid high-temperature aerobic fermentation system fermentation odor control system includes an odor heat exchange condenser A, an induced draft fan 102, a biological deodorization filter tower 103, solenoid valves 104, 105 and a temperature sensor 106, and the solid high-temperature aerobic fermentation system The exhaust port of 101 is connected to the odor inlet flange 609 of the odor heat exchange condenser A, and the odor exhaust flange 608 of the odor heat exchange condenser A is connected to the input end of the induced dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com