Odor heat exchange condensation system and method

A condensing system and odor technology, applied in the field of pollution control, can solve the problems of heat energy waste, reduce deodorization effect, aggravate environmental pollution, etc., achieve the effect of harmonious and unified energy recycling and ensure deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

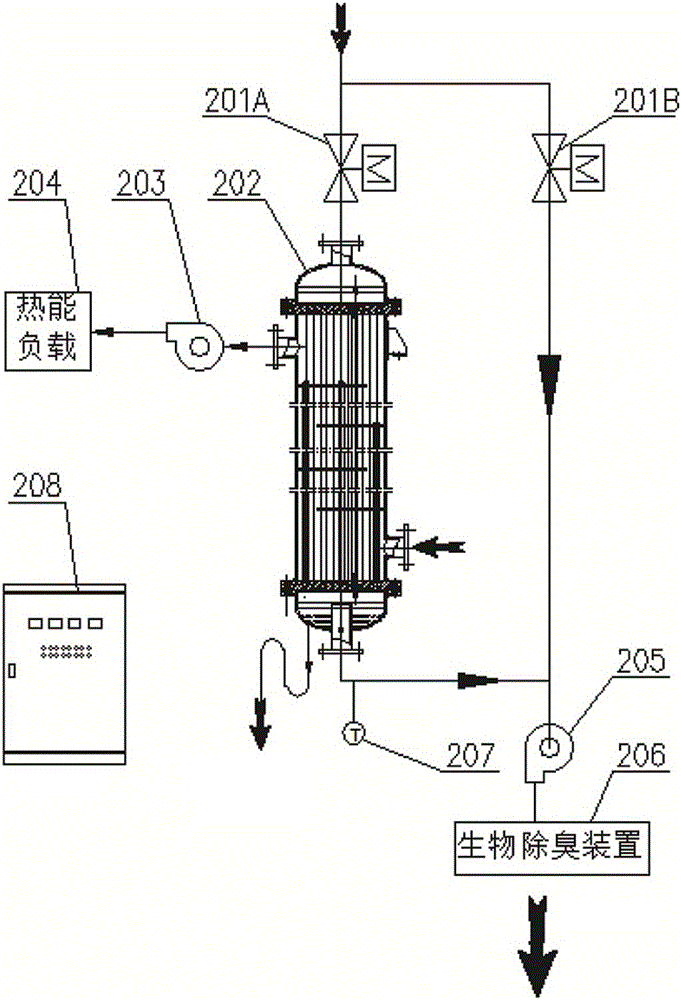

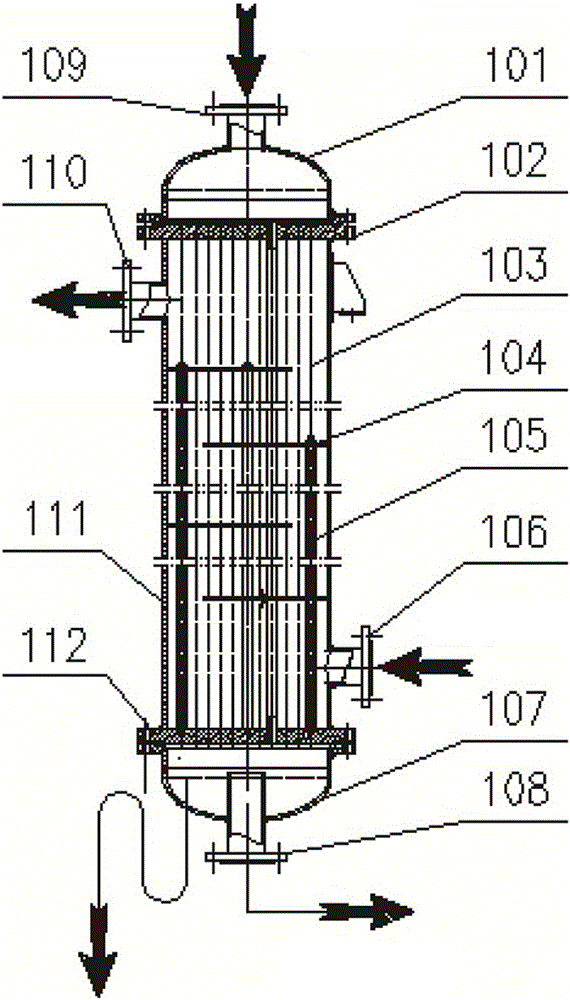

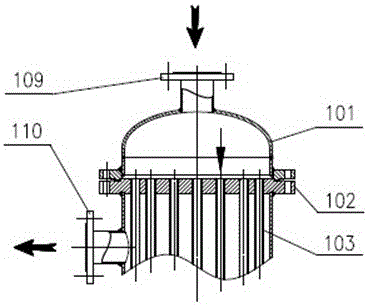

[0034] see figure 1 , figure 2 , image 3 and Figure 4 , a kind of odor heat exchange condensation system of the present invention, comprises heat exchange condenser, temperature sensor, biological deodorization device, detection and control device, odor collection pipe and odor exhaust pipe, described heat exchange condenser includes Connect the fixed upper end cover, tank body, and lower end cover in sequence. The upper end of the upper end cover has an odor inlet flange, the lower end of the odor collection pipe is connected and fixed with the odor inlet flange, and the lower end of the lower end cover has an odor exhaust method. Lan, the odor exhaust flange is fixedly connected to the odor exhaust pipe, the odor exhaust pipe is connected to the inlet of the induced draft fan, and the exhaust port of the induced draft fan is connected to the biological deodorization device; A bypass branch and a bypass branch electromagnetic valve are also connected between the ports; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com