Complex gel fragrance slow release particles and preparation method and application thereof

A technology of composite gel and slow-release granules, applied in application, tobacco, e-liquid filter and other directions, can solve the problems of difficult production and operation control, volatile aroma substances, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

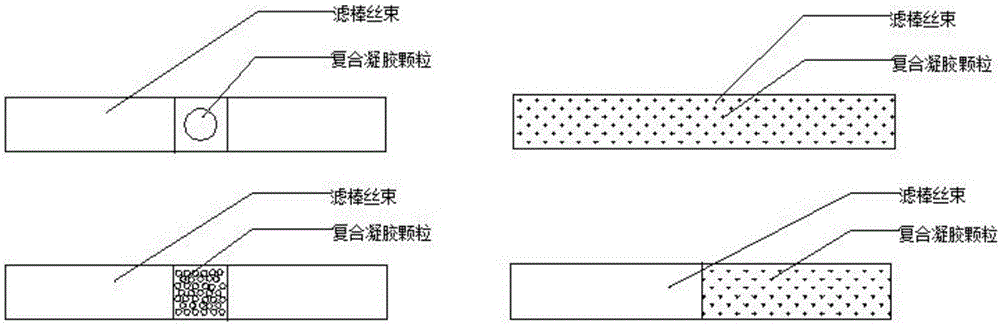

Image

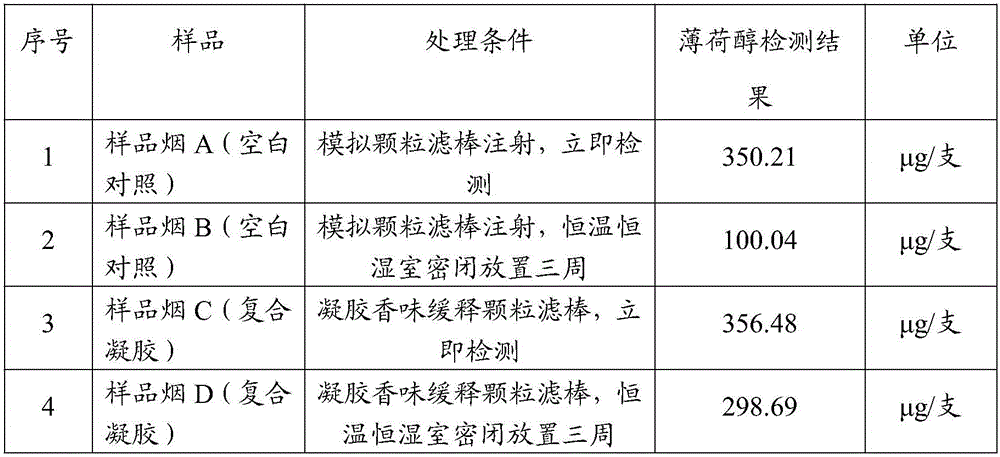

Examples

Embodiment 1

[0074] Embodiment 1: Preparation of gel flavor sustained-release granules of the present invention

[0075] The implementation steps of this embodiment are as follows:

[0076] A. Preparation of raw material mixture solution

[0077] 25 parts by weight of β-cyclodextrin, 30 parts by weight of chemically modified starch, 15 parts by weight of hydroxypropyl methylcellulose, 10 parts by weight of sodium carboxymethylcellulose, 5 parts by weight of gellan gum, and 8 parts by weight of gelatin 1. Mix 1 part by weight of chitosan with 1 part by weight of sodium citrate to obtain a powdery material, then add water to the powdery material according to the weight ratio of the powdery material to water as 1:2, stir and mix , dissolving the powdery material to obtain a raw material mixture solution.

[0078] B. Preparation of composite gel

[0079] Heat the polyethylene glycol to a temperature of 45°C to completely melt it, and then mix the melted polyethylene glycol with the raw mate...

Embodiment 2

[0086] Embodiment 2: Preparation of gel flavor sustained-release granules of the present invention

[0087] The implementation steps of this embodiment are as follows:

[0088] A. Preparation of raw material mixture solution

[0089] 30 parts by weight of β-cyclodextrin, 25 parts by weight of bio-modified starch, 18 parts by weight of hydroxypropyl methylcellulose, 6 parts by weight of sodium carboxymethylcellulose, 8 parts by weight of gellan gum, and 7 parts by weight of gelatin 1. Mix 3 parts by weight of chitosan and 2 parts by weight of sodium citrate evenly to obtain a powdery material, then add water to the powdery material according to the weight ratio of the powdery material to water at 1:3, stir and mix , dissolving the powdery material to obtain a raw material mixture solution.

[0090] B. Preparation of composite gel

[0091] Heat the polyethylene glycol to a temperature of 30°C to completely melt it, and then mix the melted polyethylene glycol with the raw mate...

Embodiment 3

[0094] Embodiment 3: Preparation of gel flavor sustained-release granules of the present invention

[0095] The implementation steps of this embodiment are as follows:

[0096] A. Preparation of raw material mixture solution

[0097] 20 parts by weight of β-cyclodextrin, 40 parts by weight of physically modified starch, 20 parts by weight of hydroxypropyl methylcellulose, 8 parts by weight of sodium carboxymethylcellulose, 10 parts by weight of gellan gum, and 5 parts by weight of gelatin 1. Mix 2 parts by weight of chitosan with 1.5 parts by weight of sodium citrate to obtain a powdery material, then add water to the powdery material according to the weight ratio of the powdery material to water at 1:2.4, stir and mix , dissolving the powdery material to obtain a raw material mixture solution.

[0098] B. Preparation of composite gel

[0099] heating the polyethylene glycol to a temperature of 80°C to completely melt it, and then mixing the molten polyethylene glycol with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com