Additive agent for perfuming tobacco thin sheet

A technology of tobacco flakes and additives, which is applied in the fields of flavoring additives and flavoring additives for tobacco flakes, and can solve the problems of lack of research and application reports on flavoring additives for tobacco flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

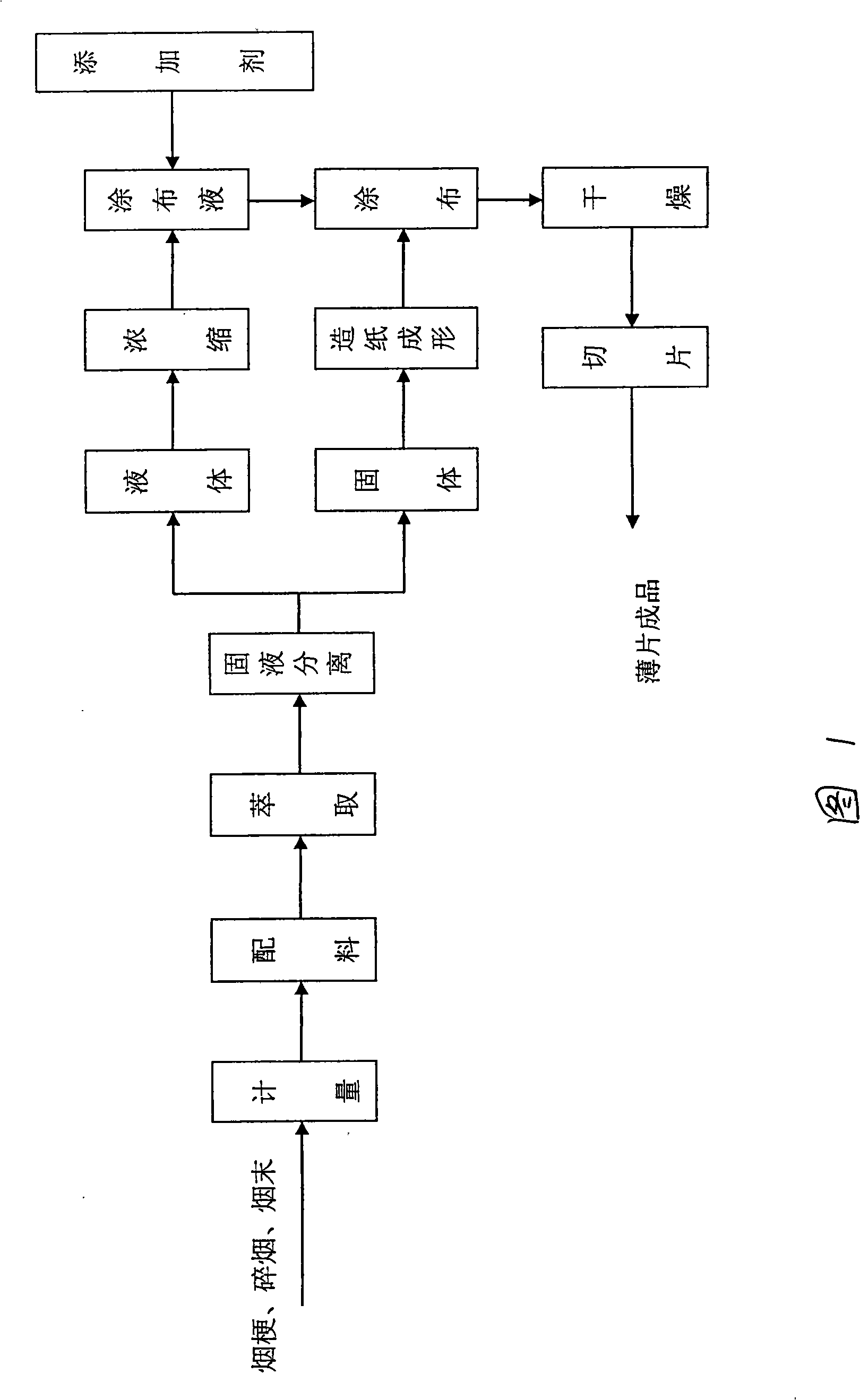

Method used

Image

Examples

Embodiment 1

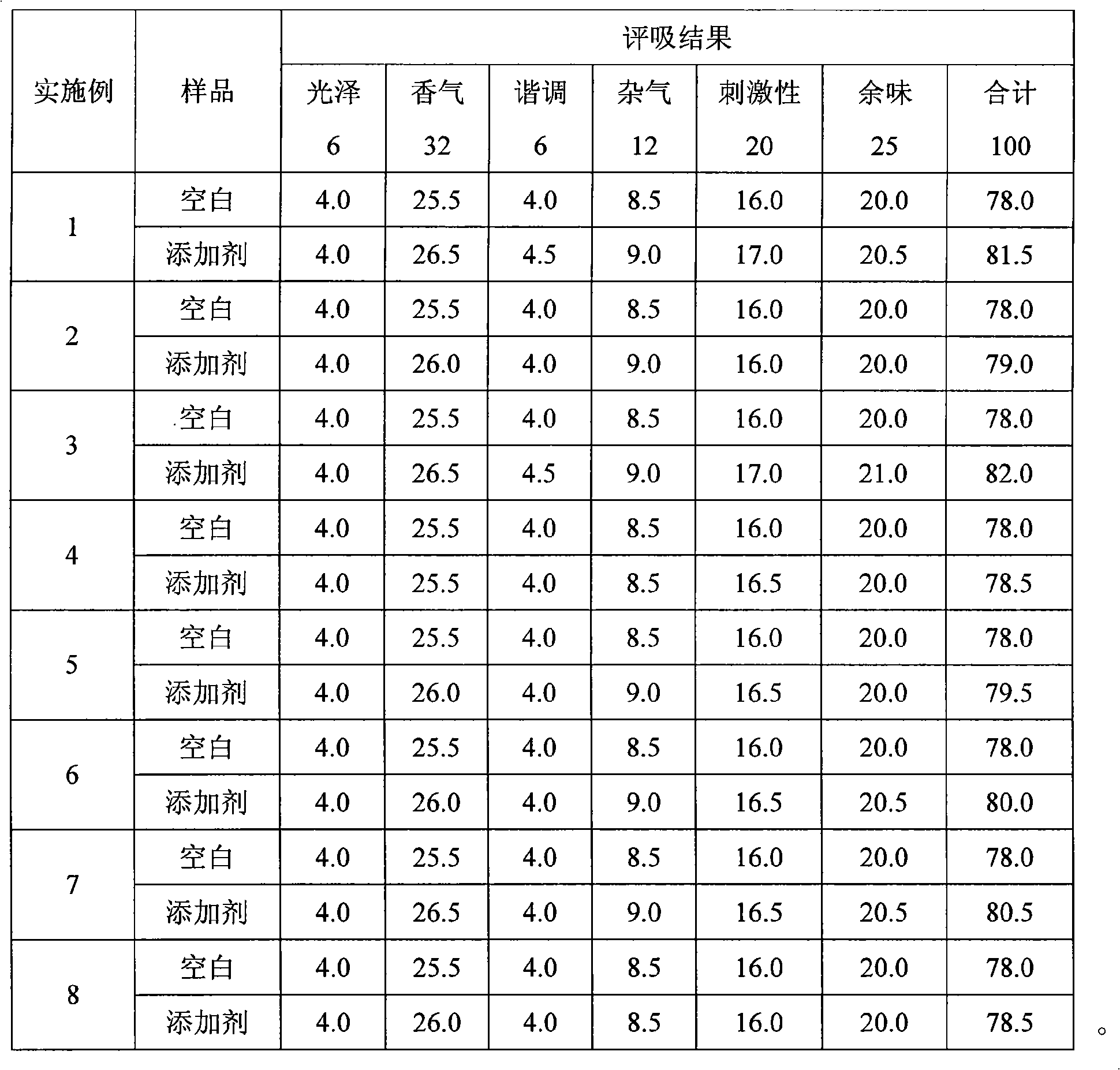

[0038] Example 1: Taking the percentage by weight of each raw material in the tobacco sheet coating solution as a unit, respectively take 4.5% of tobacco extract, 0.7% of deoxyfructosazine, 0.06% of oxidized isophorone, 0.5% of caramel balm, and 1.5% of propylene glycol %, 1.5% sorbitol, 1.50% potassium citrate, and the above raw materials are fully mixed with the coating liquid, and used in the preparation of tobacco sheets in the coating process. Then blend the shredded shreds into cigarette shreds according to the proportion of 20% by weight, and take another shredded shreds without additives and blend them into the same shredded cigarettes in the same ratio of 20% as a control sample, and evaluate them after making cigarettes. Suck. The evaluation results are shown in Table 3.

Embodiment 2

[0039] Example 2: Taking the weight percent of each raw material in the tobacco sheet coating solution as a unit, respectively take 4.0% of tobacco extract, 0.4% of deoxyfructosazine, 0.10% of oxidized isophorone, 0.20% of caramel balm, xylose Alcohol 0.4%, propylene glycol 2.3%, potassium citrate 1.4%, and the above raw materials are fully mixed with the coating liquid, and used in the preparation of tobacco sheets in the coating process. All the other are the same as Example 1, and the results of smoking are shown in Table 3.

Embodiment 3

[0040] Example 3: Taking the percentage by weight of each raw material in the tobacco sheet coating solution as a unit, respectively take 3.5% of tobacco extract, 0.80% of deoxyfructosazine, 0.06% of oxidized isophorone, 0.3% of caramel balm, and 3.0% of propylene glycol %, potassium tartrate 0.6%, and the above-mentioned raw materials are fully mixed with the coating liquid, and used in the preparation of tobacco sheets in the coating process. All the other are the same as Example 1, and the results of smoking are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com