Natural flavoring agent and flavoring paste and seasoner prepared from natural flavoring agent

A natural flavoring agent and seasoning technology, applied in the field of food science, can solve the problems of simplicity and narrow umami taste range, and achieve the effect of strong aftertaste and kokumi, thick taste, and filling the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

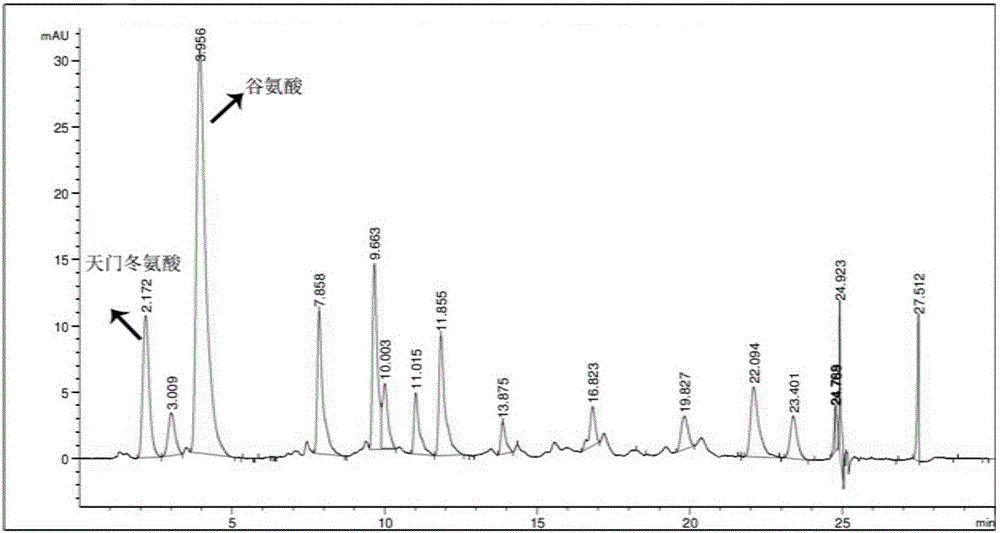

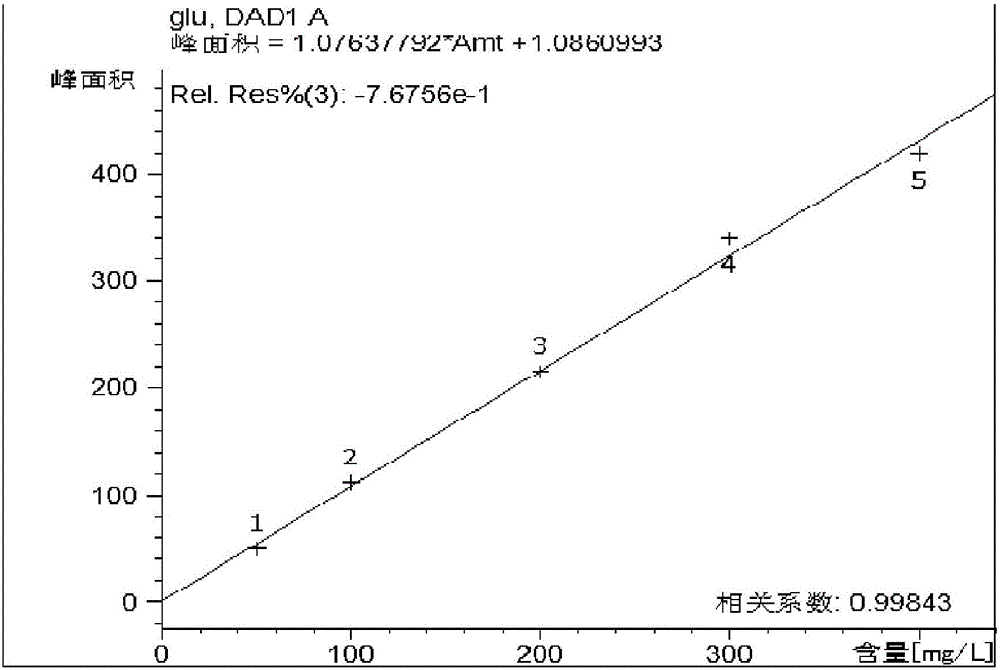

Image

Examples

Embodiment 11

[0055] This embodiment relates to a kind of natural flavoring agent, adopts the following method to prepare:

[0056] (1) Weigh 550g of pretreated old hen, 250g of beef bone, 100g of duck, 10g of scallop, 15g of hazel mushroom, 15g of bisporus mushroom, 10g of boletus, 10g of shiitake mushroom, and 0.5g of green onion. ~2min to remove the blood foam, let off the waste water, and get the preparatory material;

[0057] (2) Mix the preparatory material with water at a volume ratio of 1:2, boil for 3 hours at 100°C, and cool to room temperature to obtain a mixed material;

[0058] (3) Mix the mixture with water at a volume ratio of 1:3, heat to 40°C, adjust the pH to 7.0, add 2 g each of Protamex (composite protease) and Flavourzyzme (composite flavor protease), stir for 4 hours, and extinguish After the enzyme is cooled, the enzymatic hydrolysis solution is obtained;

[0059] (4) After filtering the enzymolysis solution with gauze, centrifuge at 4°C and 7000rpm for 10min, remov...

Embodiment 12

[0061] This embodiment also provides the natural seasoning paste comprising the natural flavoring agent described in this embodiment, which is prepared by the following method:

[0062] Get 13 parts of natural flavoring agent, mix with 85 parts of hydrolyzed vegetable protein liquid and 7 parts of I+G.

[0063] The hydrolyzed vegetable protein liquid is gluten hydrolyzed protein liquid.

Embodiment 13

[0065] This embodiment also provides a natural seasoning comprising the natural seasoning paste described in this implementation, which is prepared by the following method:

[0066] Get 40 parts of the natural flavor paste, mix with 35 parts of table salt, 3 parts of granulated sugar, 8 parts of starch, 1 part of essence and 1 part of water;

[0067] Put the above mixture into a mixing tank, stir and mix until evenly mixed, and granulate through a rotary granulator to obtain granular natural seasoning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com