Concentration constant control method for water-soluble fertilizers

A constant control and concentration technology, applied in the field of water-soluble fertilizer, can solve the problems of difficult concentration ratio, fertilizer waste, high and low concentration, etc., and achieve the effect of uniform concentration distribution, high stirring efficiency and precise fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

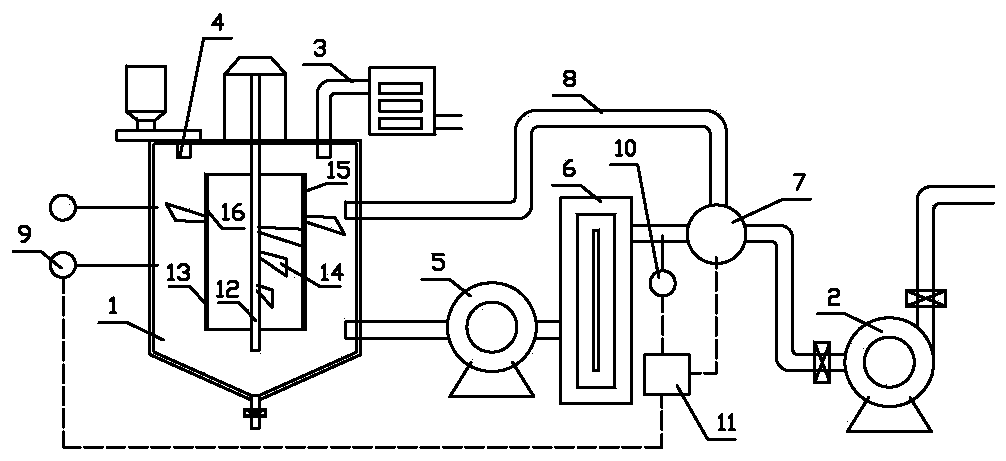

[0020] Such as figure 1 As shown, the constant concentration fertilization equipment for water-soluble fertilizer according to the present invention comprises a stirring tank 1, a water pump 2 arranged at the output end of the stirring tank 1, a water injection pipe 3 and a fertilizer input pipe 4 arranged at the input end of the stirring tank 1, through which the water injection pipe 3 and the fertilizer input pipe 4 inject the water-soluble fertilizer and water into the mixing tank 1 in proportion, and after stirring and mixing evenly, they are output through the water pump 2 for fertilization operations.

[0021] The booster pump 5 is connected to the output end of the stirring tank 1, and the output end of the booster pump 5 is connected to a two-position three-way valve 7 through a filter 6. The filter 6 can filter out insoluble impurities on the one hand and on the other hand It also allows better distribution of water and fertilizer. The water pump 2 is connected to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com