Circuit board with embedded magnetic core and manufacturing method for circuit board

A manufacturing method and circuit board technology, applied in the directions of printed circuits, printed circuits, assembling printed circuits with electrical components, etc., can solve problems such as unfavorable product miniaturization and high density, large inductance of power supply parts, and poor solder joints, etc. Achieve the effect of being conducive to miniaturization and high densification, saving area and eliminating welding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

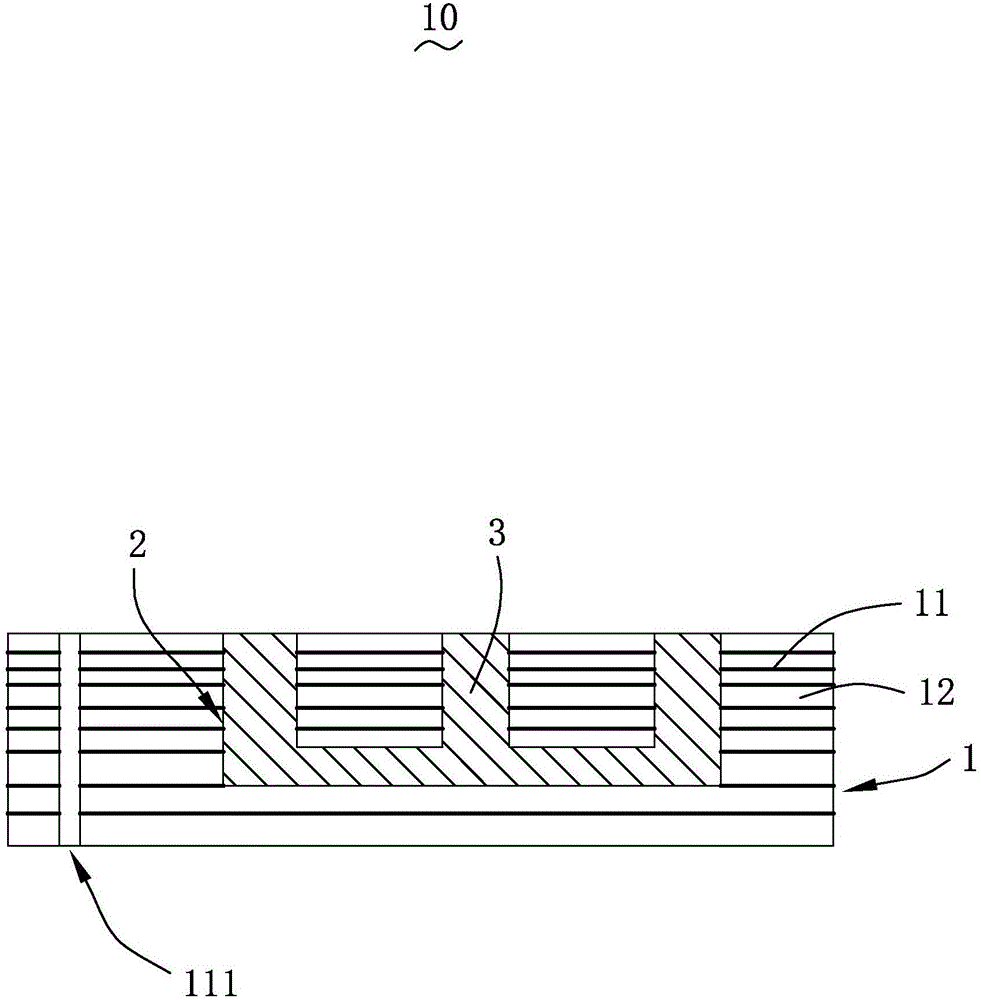

[0026] see figure 1 , is a structural schematic diagram of the embedded magnetic core circuit board of the present invention. The embedded magnetic core circuit board 10 provided by the present invention includes a PCB main board 1 , an embedding groove 2 recessed into the PCB main board 1 , and a magnetic core 3 placed in the embedding groove 2 .

[0027] The PCB main board 1 includes a multi-layer copper plating layer 11 stacked sequentially from the bottom to the top surface and a PP layer 12 sandwiched between two adjacent layers of the copper plating layer 11 for forming the copper plating layer 11. Insulation between layers 11. The copper plating layer 11 includes a conductive through hole 111 penetrating through it and plated with copper inside, for realizing the communication between the copper plating layers 11 . The copper plating layer 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Copper thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com