2121RGB lamp bead bracket and die bonding method

A 2121RGB, lamp bead technology, applied in the field of 2121RGB lamp bead bracket and solid crystal, can solve the problems of solder joint detachment, influence of ceramic nozzle life, increase production cost, etc., to improve stability and reliability, and avoid bad two solder joints , The effect of improving the welding wire problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

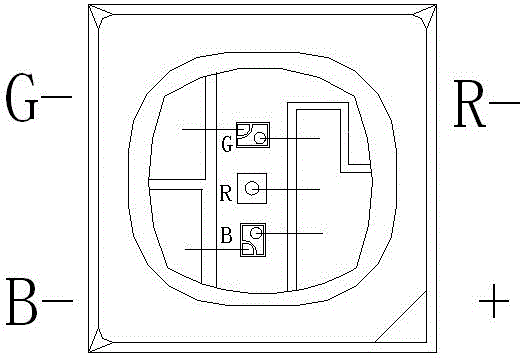

[0014] Such as figure 1 As shown, a 2121RGB lamp bead bracket of the present invention has a bowl inside the bracket, and the bottom of the bowl is divided into multiple areas by an isolation belt, and one side of the chip fixing area in the bowl is provided with G- and B- two The solder joint area and the other side are provided with the R-second solder joint area, the upper isolation strip of the R-second solder joint area is bent upwards to expand the solder area, and the G chip, R chip and B chip are fixed on the bowl in a straight line. In the bottom chip fixing area, the G chip and the B chip correspond to the level of the G- and B- two pads respectively and are connected through gold wire welding. The G chip, R chip and B chip are all horizontally corresponding to the R-2 pad Conduction is conducted through gold wire welding, and fixed gold balls are spot-welded at both ends of all gold wires, and encapsulation colloid for sealing and protecting chips is provided in all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com