Automatic cleaning and lubricating device for conveying chain block of linear edge sealing equipment

A lubricating device and automatic cleaning technology, applied in the direction of cleaning devices, cleaning methods using gas flow, conveyor objects, etc., can solve the problems of splashing to each unit of the fuselage, affecting the flexibility of the link, and the chain block cover falling off, etc., to achieve The effect of avoiding manual labor, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

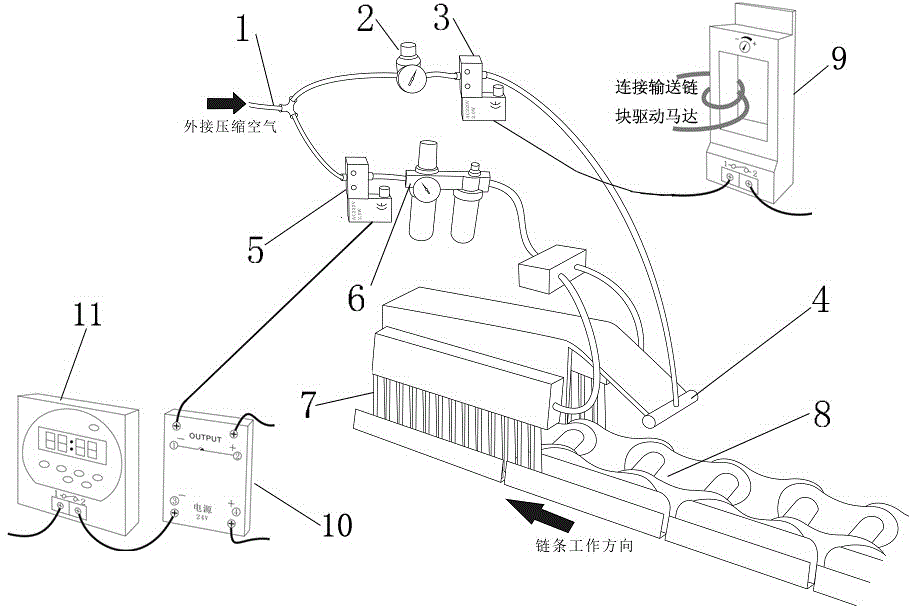

[0012] figure 1 Shown is an automatic cleaning and lubricating device for the conveying chain of linear edge banding equipment. The conveying chain 8 is driven by the driving motor of the conveying chain. The automatic cleaning and lubricating device includes two parts: a cleaning device and a lubricating device. The cleaning device includes a cleaning regulating valve 2, Clean solenoid valve 3, blowing rod 4 and current relay 9; Lubricating device includes oiling solenoid valve 5, pneumatic triple piece 6, oiling brush 7, solid state relay 10 and programmable time controller 11; Cleaning device and lubricating device are all with The compressed air hose 1 is connected, and the compressed air hose 1 is connected with the external compressed air. The current relay 9 is connected to the driving motor of the conveying chain block and connected to control the cleaning solenoid valve 3; when the driving motor of the conveying chain block is started, the current relay 9 works, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com