Energy-efficient closed-cycle spray drying system

A closed-circuit circulation and drying system technology, applied in spray evaporation, evaporator adjustment/control, evaporator accessories, etc., can solve the problem of large water evaporation, achieve the effects of ensuring chemical properties, reducing pollution, and increasing output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

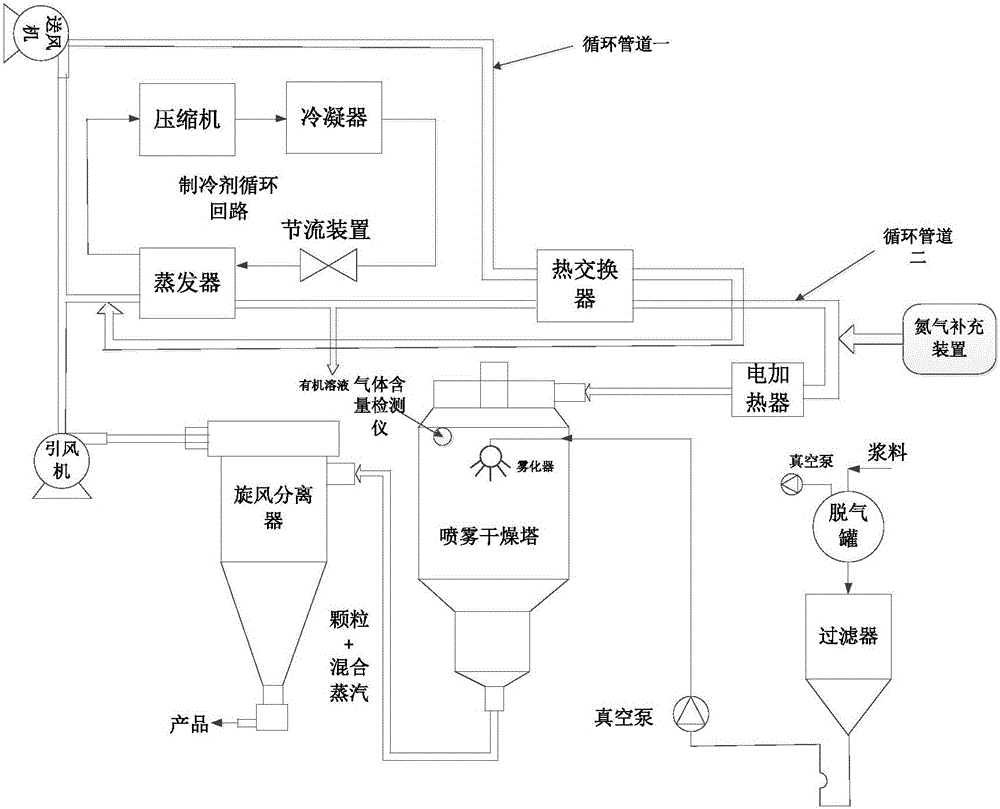

[0030] Dry the cemented carbide mixture with alcohol as the solvent. As shown in the figure, the slurry is firstly sent to the degassing tank by the vacuum pump to increase the power to separate the air in the slurry, and then sent to the filter to filter the slurry. The slurry is pressurized by a vacuum pump and sent to the atomizer located in the spray drying tower for atomization. Because the spray drying tower is filled with high-temperature nitrogen, the spray drying tower is filled with high temperature nitrogen, so the mist slurry and the working steam conduct contact heat exchange, so that The slurry dries instantaneously to form a granular product while generating mixed steam. The product enters the cyclone separator with the working gas, and the cemented carbide mixture particles are discharged from the bottom of the cyclone separator. The mixed steam enters the circulation pipe 1 and the circulation pipe 2 through the induced draft fan. The mixed steam entering the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com