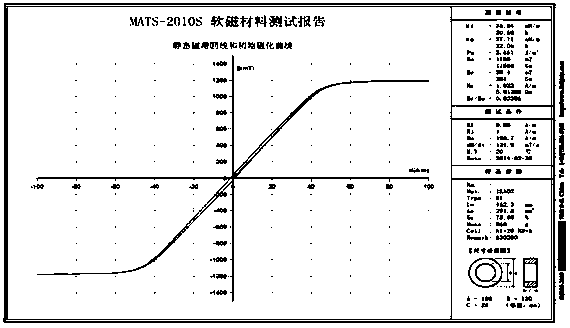

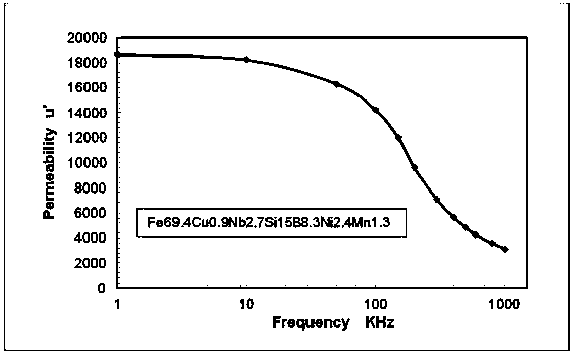

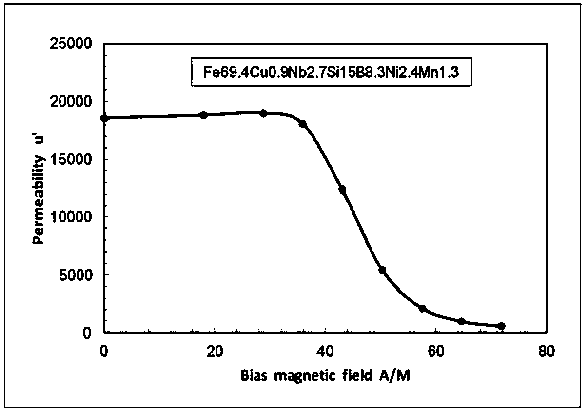

A nanocrystalline magnetic core with linear magnetic permeability and its preparation method

A nanocrystalline, magnetic permeability technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, magnetic objects, etc. Effect of core loss, strong anti-saturation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0060] The magnetic cores in Examples 1-3 conform to the above-mentioned alloy ratio and are prepared by the following preparation method. The preparation method specifically includes the following steps:

[0061] (1) carry out the spraying system of alloy melt to the alloy of described component by quenching single roll method, form crystalline state alloy strip material;

[0062] (2) according to the requirement, the strip is cut with a fixed width roller, and then wound to make a ring magnetic core of a certain size;

[0063] (3) Place the iron core in a nitrogen protection furnace, and at the same time apply a magnetic field strength greater than 5Am along the axial direction of the annular iron core -1 The transverse magnetic field is used to raise the temperature to the crystallization temperature for crystallization and stress relief heat treatment. The temperature during the heat treatment is 510°C to 570°C, the average heating rate during heat treatment is 2°C to 10°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com