Detection device for copper powder on matte surface of electronic copper foil and method

A detection device, electronic copper foil technology, applied in the direction of measuring device, material analysis through optical means, instrument, etc. Surface copper powder status and other issues to achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

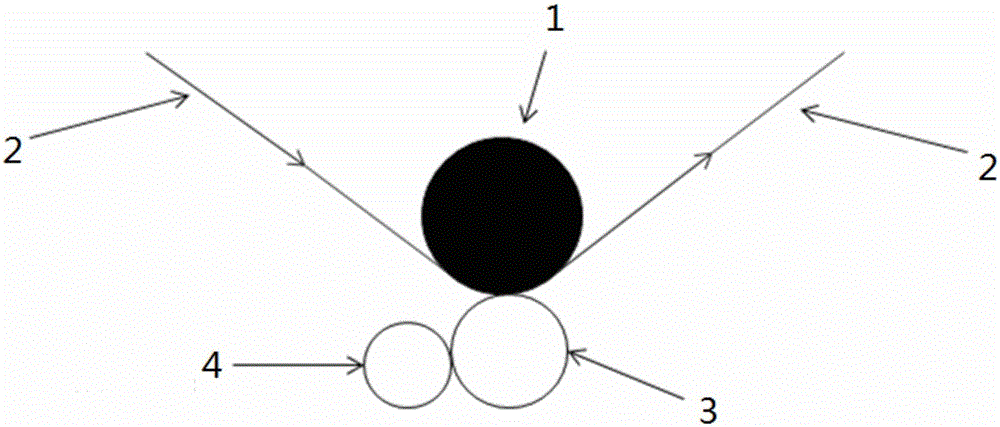

[0029] Combine the sticky roller with the rough surface of the copper foil at a pressure of 0.35MPa, and combine the sticky paper roll with the sticky roller at a pressure of 0.42Mpa. , transfer the copper powder on the rough surface of the copper foil to the sticky paper. After sticking the dust for 900 meters, remove the sticky paper from the sticky paper roll, and observe the condition of the copper powder on the sticky paper through a metallographic microscope to reflect the copper Condition of copper powder on foil matte side.

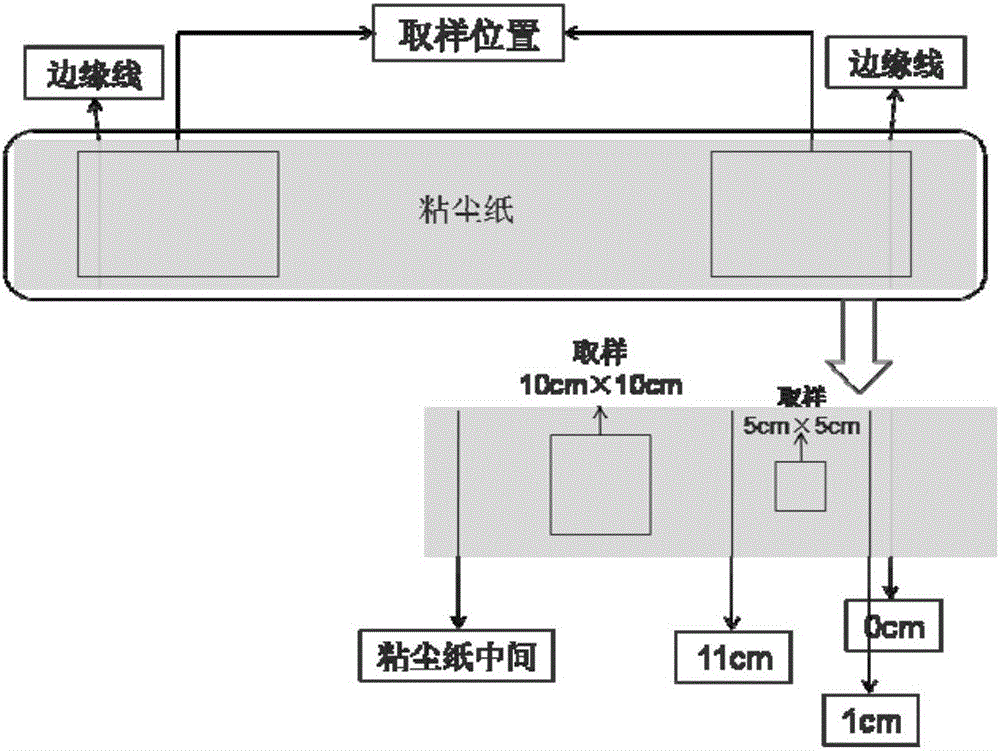

[0030] Sampling method according to figure 2 In the method shown, sample 5cm×5cm and 11cm-11cm-sticky paper on both sides of the sticky paper at a distance of 1-11cm from the edge line. Take a sample and observe the size and quantity of copper powder with a metallographic microscope. As a result, it is possible to avoid the destruction of nodules generated by electroplating on the matte surface of the copper foil, and to clearly and truly observ...

Embodiment 2

[0032] Combine the sticky roller with the rough surface of the copper foil at a pressure of 0.55MPa, and combine the sticky paper roll with the sticky roller at a pressure of 0.49MPa. , transfer the copper powder on the rough surface of the copper foil to the sticky paper. After sticking the dust for 900 meters, remove the sticky paper from the sticky paper roll, and observe the condition of the copper powder on the sticky paper through a metallographic microscope to reflect the copper Condition of copper powder on foil matte side.

[0033] When observing copper powder with sticky paper, the sampling method is as follows figure 2 In the method shown, sample 5cm×5cm and 11cm-11cm-sticky paper on both sides of the sticky paper at a distance of 1-11cm from the edge line. Take a sample and observe the size and quantity of copper powder with a metallographic microscope. As a result, it is possible to avoid the destruction of nodules generated by electroplating on the matte surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com