Femtosecond laser micromachining-based optical fiber Mach-Zehnder's sensor and manufacturing method thereof

A femtosecond laser and sensor technology, applied in the direction of phase influence characteristic measurement, etc., can solve the problems of complex manufacturing process, limitation, inconvenient mass production, etc., and achieve the effect of easy processing, small size, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe in detail below in conjunction with accompanying drawing:

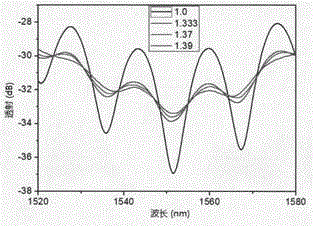

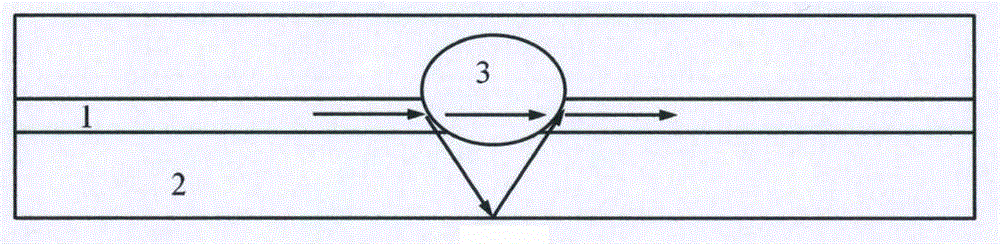

[0022] figure 1 , an optical fiber Mach-Zehnder sensor based on femtosecond laser micromachining, including a core 1, a cladding 2, and an air bubble 3; the air bubble 3 is located in the optical fiber and is elliptical, with a major axis of 50 μm and a minor axis of 40 μm , the distance between the center of the air bubble and the center of the fiber core is 8-10 μm.

[0023] A method for fabricating an optical fiber Mach-Zehnder sensor based on femtosecond laser micromachining, comprising the following steps:

[0024] (1) Take the single-mode optical fiber, strip the coating layer of the optical fiber with a fiber stripper, and cut out a clean end face of the optical fiber with a cleaver;

[0025] (2) Femtosecond laser micromachining is adopted, the laser wavelength is 800nm, the repetition frequency is 1KHz, the pulse width is 120fs, and the maximum output power is 100mW, which is adjusted to abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis | aaaaa | aaaaa |

| Short axis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com