A continuous digestion system with adjustable pressure and flow

An adjustable, flow rate technology, applied in the field of digestion, can solve the problems of low automation efficiency, uncontrollable pressure, environmental hazards, etc., and achieve the effects of easy operation, small pressure fluctuation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

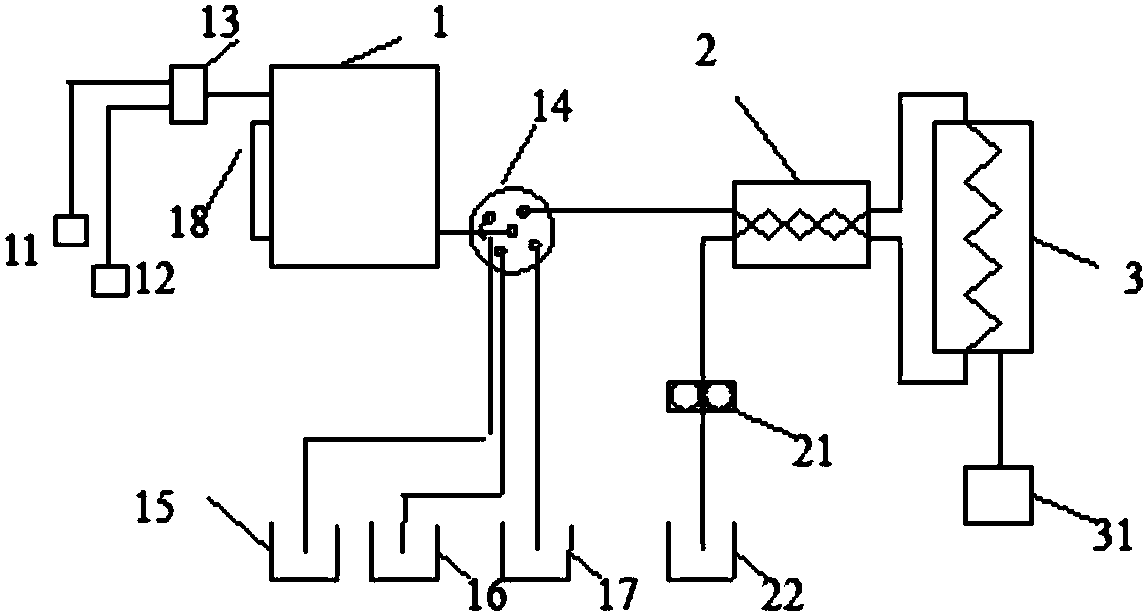

Embodiment 1

[0030]A pressure and flow adjustable continuous digestion system, the system includes a liquid sample storage tank 1, a heat exchange tube 2, and a thermal digestion device 3 connected in sequence, and the upper end of the liquid sample storage tank 1 is respectively connected to the air via a three-way solenoid valve 13 Pump 11 and vacuum pump 12; the liquid sample storage tank 1 is respectively connected to a cleaning solution bottle 15, a digestion reagent bottle 16, a digestion sample bottle 17 containing a liquid to be digested, and a heat exchange tube 2 through a four-way valve 14, and the heat exchange tube 2 There are two intertwined pipelines, one end of which is connected to the liquid sample storage tank 1 through the four-way valve 14, and the other end is connected to the liquid inlet of the thermal digestion device 3; one end of the other pipeline is connected to the heat The other end of the liquid outlet of the digestion device 3 communicates with the digestion...

Embodiment 2

[0042] Referring to Example 1, the difference is that the vacuum pump is replaced by a peristaltic pump, the thermal digestion device is an aluminum shell, the built-in glass spiral pipeline is used for microwave heating, the temperature of the digestion liquid is monitored by the built-in infrared probe, and the external temperature control device controls the microwave heating power.

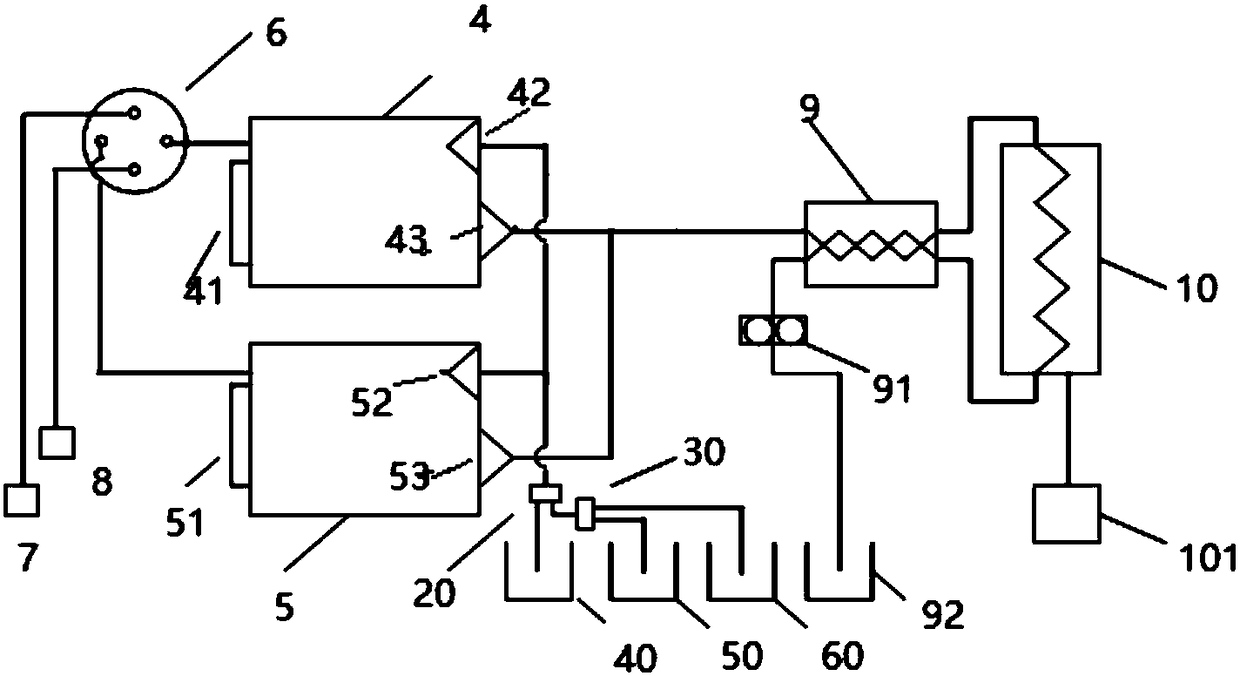

Embodiment 3

[0044] Referring to Example 1, the difference is that the liquid sample storage tank is two parallel connections of the first liquid sample storage tank 4 and the second liquid sample storage tank 5, and the specific structure is as follows figure 2 A continuous digestion system with adjustable pressure and flow is shown, the system includes a liquid sample storage tank, a heat exchange tube 9, and a thermal digestion device 10 connected in sequence, and the liquid sample storage tank is the first liquid sample storage tank 4 and Two second liquid sample storage tanks 5 are connected in parallel, and the upper ends of the first liquid sample storage tank 4 and the second liquid sample storage tank 5 are respectively connected to the air pump 8 and the vacuum pump 7 through the four-way valve 6; The first check valve 42 communicates with the first solenoid valve 20, and the upper end of the second liquid sample storage tank 5 communicates with the first solenoid valve 20 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com