Temperature sensor for interior of oil immersed transformer and manufacturing method of temperature sensor

A technology of temperature sensor and oil-immersed transformer, applied in the direction of thermometers, thermometers, thermometer parts, etc. with physical/chemical changes, can solve the problems of installation and use damage, low reliability, drift, etc., to achieve convenient monitoring, reliable High performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

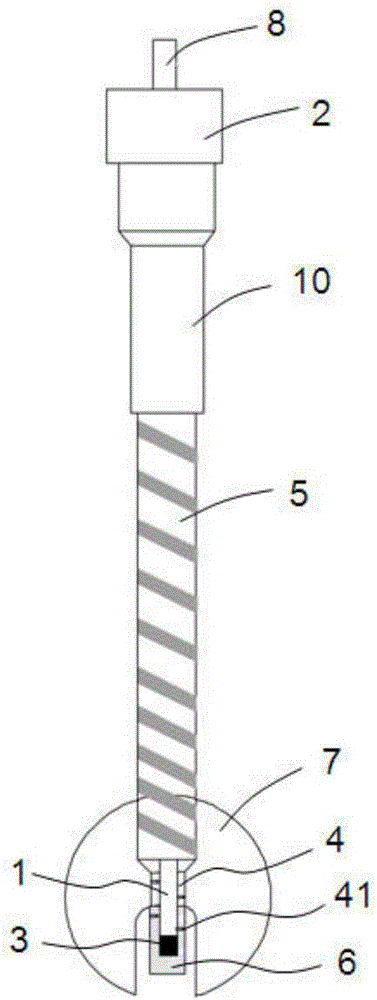

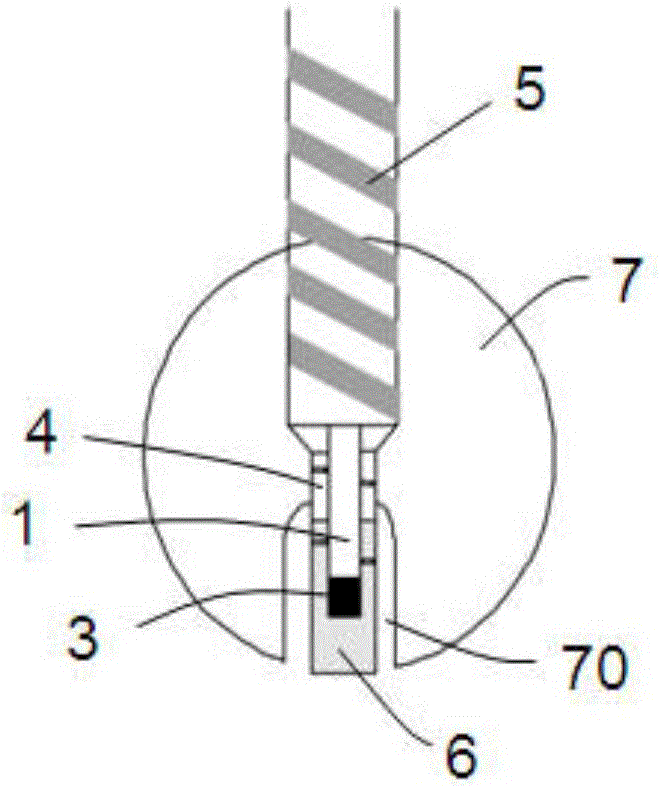

[0031] refer to figure 1 , the temperature sensor for the interior of the oil-immersed transformer according to the embodiment of the present invention includes an optical fiber 1, an optical fiber connector 2 arranged at the first end of the optical fiber 1, a heat-sensitive element 3 packaged at the second end of the optical fiber 1, and a first protective sheath 4 And the second protective sleeve 5, the first protective sleeve 4 is sleeved on the outer peripheral surface of the second end of the optical fiber 1, the second protective sleeve 5 is sleeved on the other outer peripheral surface of the optical fiber 1, and the first protective sleeve 4 is provided with a radial direction through a plurality of through holes 41 . The optical fiber connector 2 can be any one of metal optical fiber connectors such as ST, FC, and SMA, which is convenient for connecting with other devices.

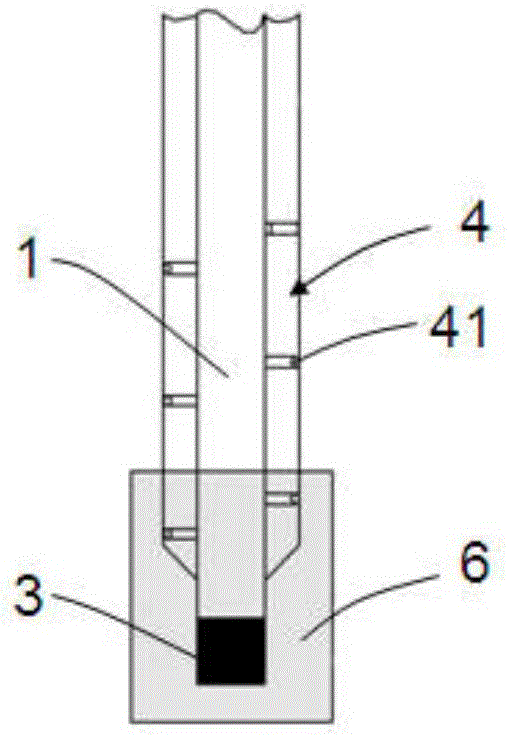

[0032] combine figure 2 As shown, the end of the first protective sheath 4 , the second en...

Embodiment 2

[0053] Such as Figure 6 As shown, different from the embodiment, the size of the fixed disk 7 of the present embodiment is smaller, the first protective cover 4 is fixed on the fixed disk 7, and the length is greater than that of the fixed disk 7, and its end protrudes from the fixed disk 7 In addition, this design can be applied to detection in a narrower space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com