Stepless speed changer and vehicle provided with stepless speed changer

A technology of continuously variable transmissions and actuators, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as liquid leakage, avoid hydraulic leakage, improve use safety, and diagnose faults and the effect of simple maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0039] The continuously variable transmission 1000 according to the embodiment of the present invention will be described in detail below with reference to the drawings and embodiments. The continuously variable transmission 1000 according to the embodiment of the present invention can be applied to vehicles, such as electric vehicles.

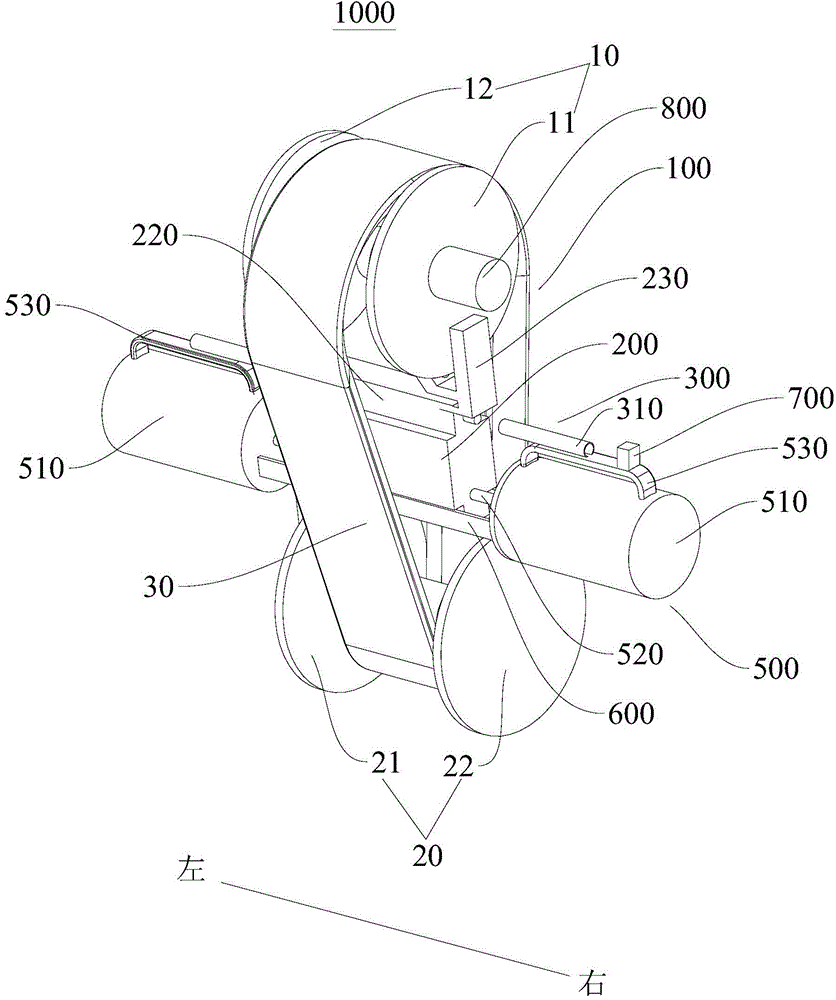

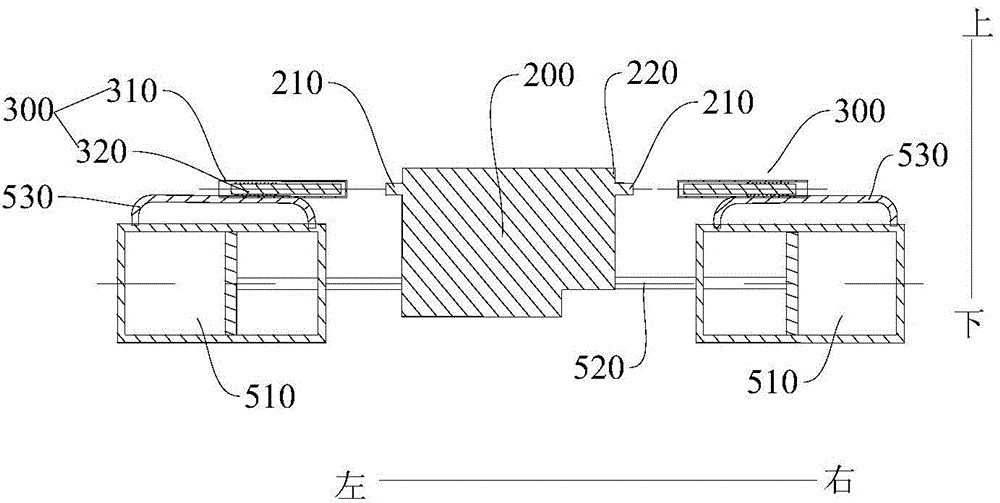

[0040] like figure 1 As shown, the continuously variable transmission 1000 according to the embodiment of the present invention may include a transmission assembly 100, an actuator 200, an actuator 200, a second magnetic component 300 and a PLC controller (programmable logic controller). combine figure 1 and figure 2 As shown, the transmission assembly 100 includes a driving wheel set 10, a driven wheel set 20 and a transmission belt 30, the driving belt 30 is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com