Automobile gear shift rod seaming

A shift lever and welding technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as complex structure and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

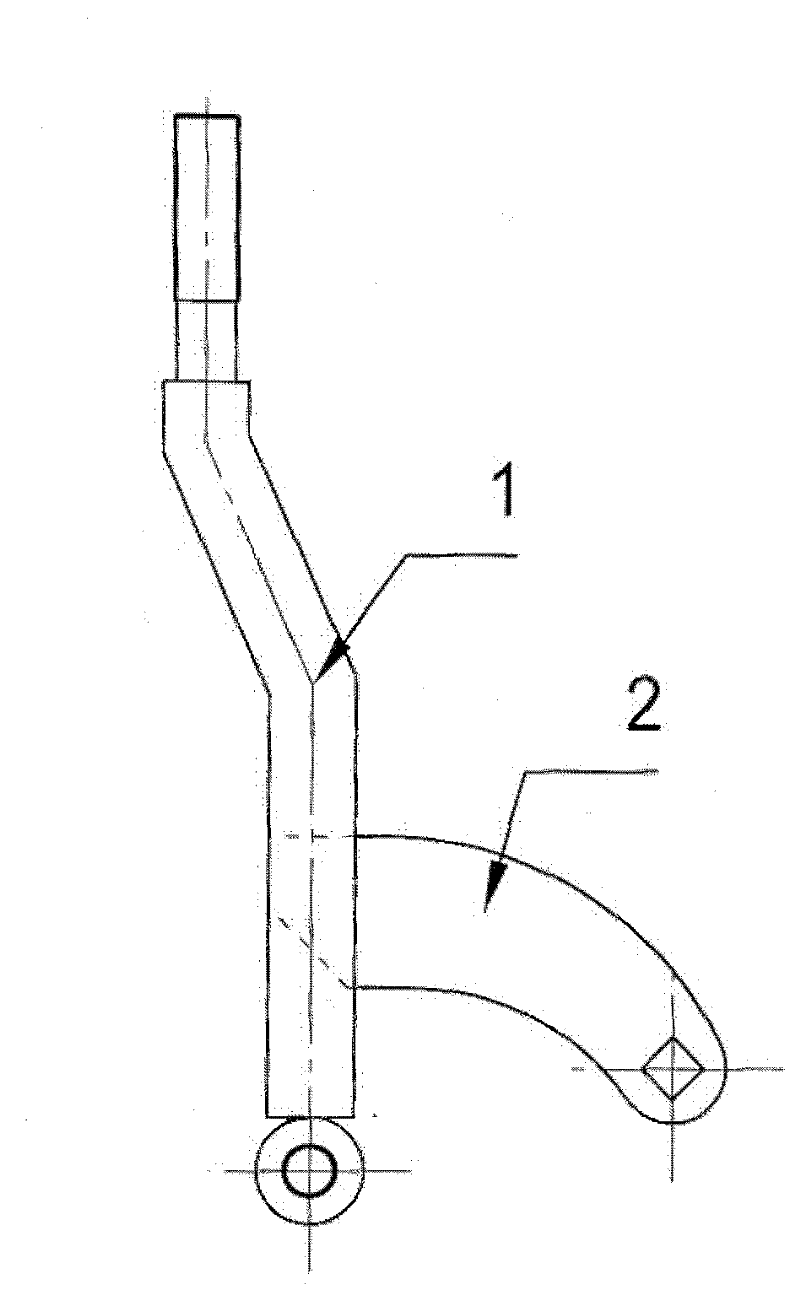

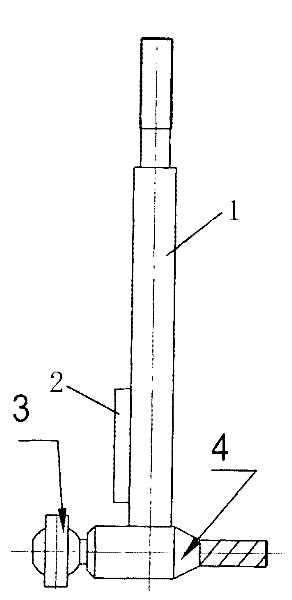

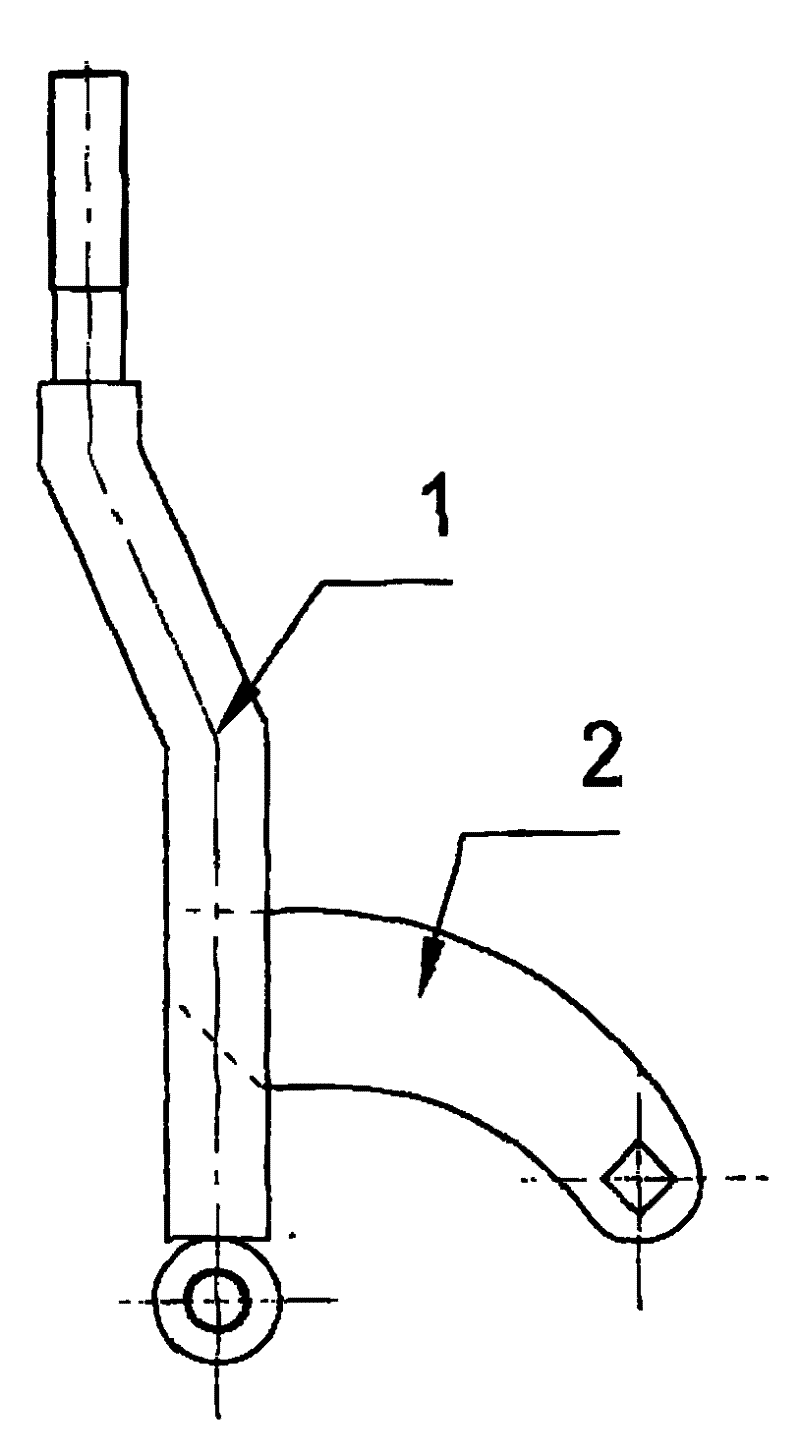

[0010] Such as figure 1 , 2 As shown, the present invention is welded with a ball joint shaft 4 at the lower end of the shift lever 1, and a joint bearing 3 is arranged at one end of the ball joint shaft 4. One end of the gear rocker arm 2 is welded together with the gear lever 1. Through the above arrangement, the other end of the arc-shaped shift rocker arm of the present invention is connected with the shift rod on the automobile gearbox to realize the speed change of the automobile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com