Executing element, valve device and air door device

A technology for actuating elements and holding parts, which is applied to valve devices, valve operation/release devices, transmission devices, etc., and can solve the problems of increasing the number of parts, unfavorable cost control, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

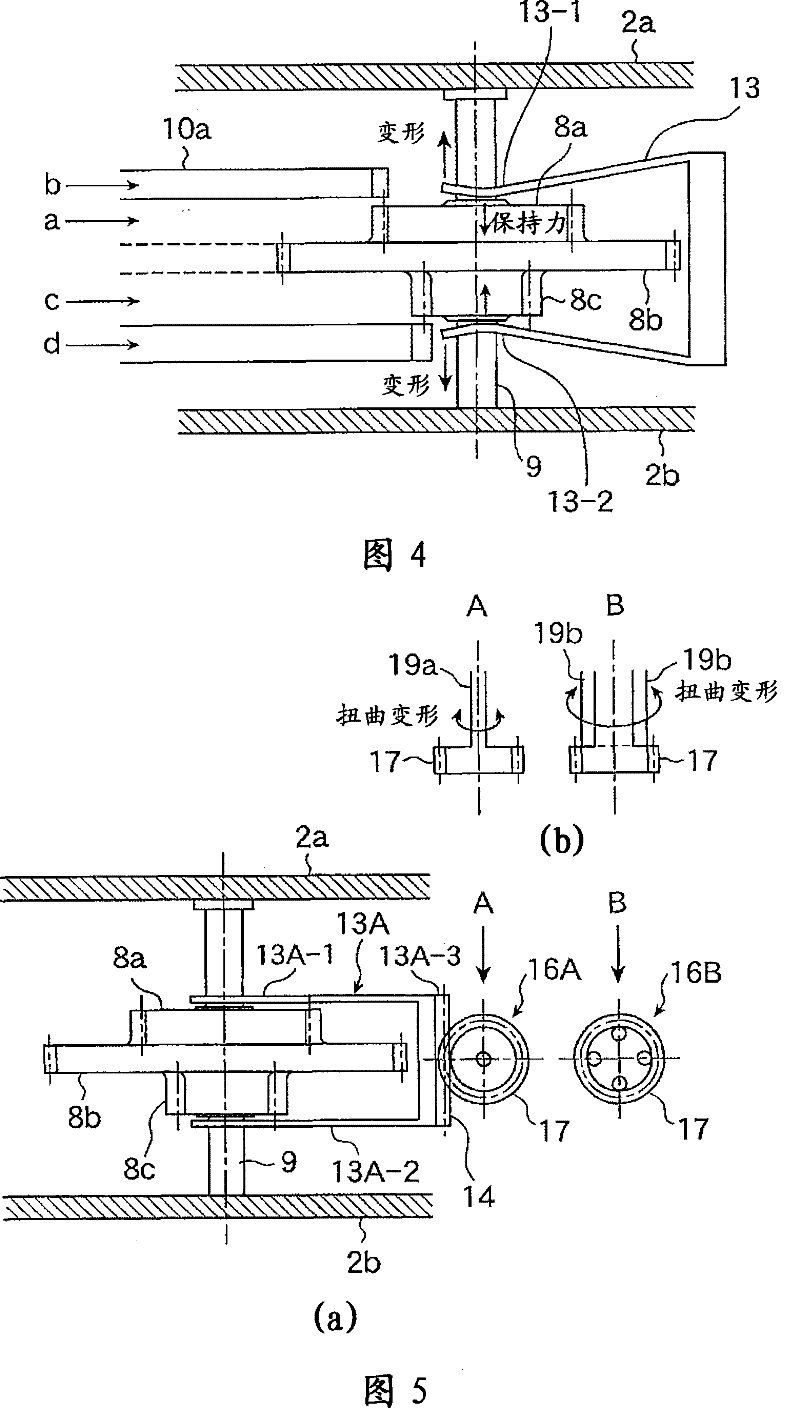

[0031] figure 1 It is a schematic diagram showing the internal mechanism of the actuator according to Embodiment 1 of the present invention. figure 2 yes means figure 1Diagram of the gear unit in . The actuator 1 according to Embodiment 1 has: support plates 2a, 2b housed in a housing; a motor 3 disposed on the support plate 2a; and an output shaft provided on the support plates 2a, 2b so as to penetrate the support plates 2a, 2b. 4. The output shaft can rotate freely; and the gear unit that transmits the torque of the motor 3 to the output shaft 4 .

[0032] The support plate 2a and the support plate 2b are arranged in parallel and spaced apart in the casing. The electric motor 3 is arranged such that its rotary shaft 5 penetrates the support plate 2 a , and a transmission gear 6 is attached to the rotary shaft 5 . The output shaft 4 of the actuator 1 is installed on the figure 1 A valve stem not shown below is connected, and the valve opens and closes in accordance ...

Embodiment approach 2

[0073] In the example shown in Embodiment 1 above, during manual operation, the connection between the manual / transmission clutch gear and the rear-stage transmission gear is cut off. The connection between the transmission gears on the front stage side.

[0074] Figure 7 It is a figure which shows the gear unit of the actuator which concerns on Embodiment 2 of this invention. Figure 7 The gear unit shown has: a transmission gear 6 fixed to a rotary shaft 5 of an electric motor 3, a manual / transmission clutch gear 22 having gear portions 22a, 22b, 22c, 22d, and a coaxially formed and integrally rotatable Transmission gears 24a, 24b, 24c.

[0075]The manual / transmission clutch gear 22 is composed of coaxially integrally formed gear portions 22a, 22b, 22c, and 22d, and is provided on the fixed shaft 23 so as to rotate around the fixed shaft 23 fixed to the support plates 2a, 2b. , and can slide along the axial direction of the fixed shaft 23. In addition, in each gear port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com