Diesel particle catcher

A particle trap, diesel technology, applied in the direction of machines/engines, mufflers, engine components, etc., can solve the problems of clogging diesel particle filters, complex regeneration control, human harm, etc., to save use costs, avoid gas blockage, Stress-relieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

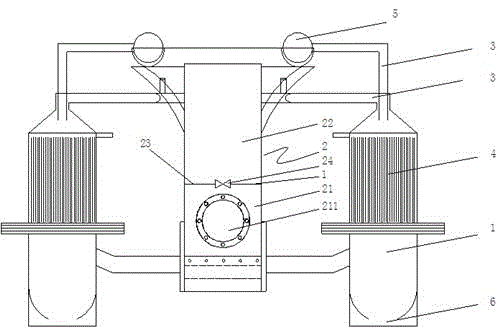

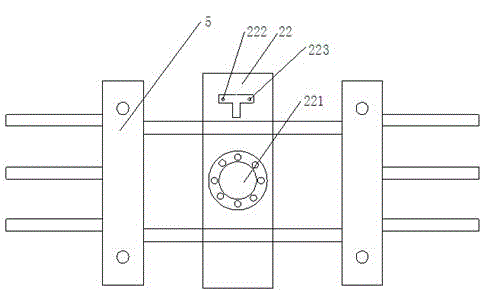

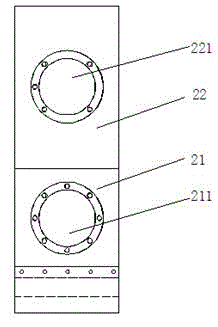

[0029] Such as Figures 1 to 6 As shown, a diesel particulate trap of the present invention includes a purification device 1 and a gas collection device 2, and the gas collection device 2 includes an exhaust gas collection box 21 at the lower end and a clean gas collection box 22 at the upper end, the exhaust gas collection box 21 and the clean gas collection box The box 22 is separated by a partition 23, the lower end of the purification equipment 1 is connected to the exhaust gas collection box 21 through the pipeline 3, the upper end of the purification equipment 1 is connected to the clean gas collection box 22 through the pipeline 3, and the diesel particle for purifying diesel oil is arranged inside the purification equipment 1. Filter 4, the top of the purification equipment 1 is connected to the gas storage tank 5 through the pipeline 3, the partition 23 between the waste gas collection box 21 and the clean gas collection box 22 is provided with a normally closed valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com