Construction method of cement-emulsified asphalt mortar injecting type semi-flexible pavement

A technology of cement-emulsified asphalt and semi-flexible pavement, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of complex supporting machinery and equipment, less application, complex construction technology, etc., and achieve simplification of construction technology , Wide range of uses, high compressive strength and high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

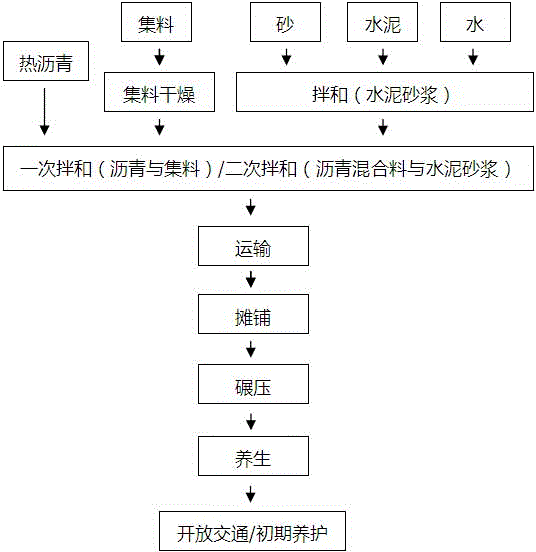

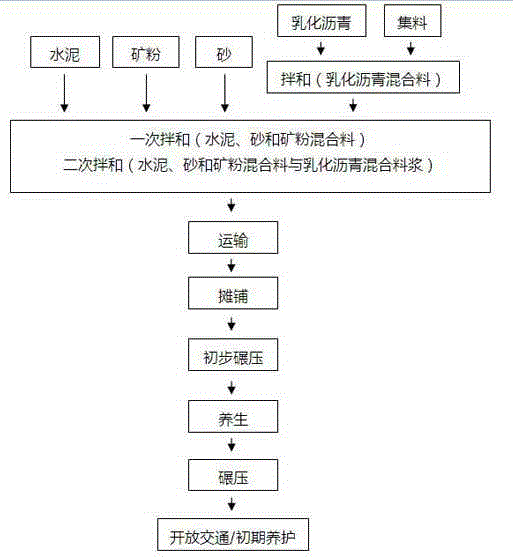

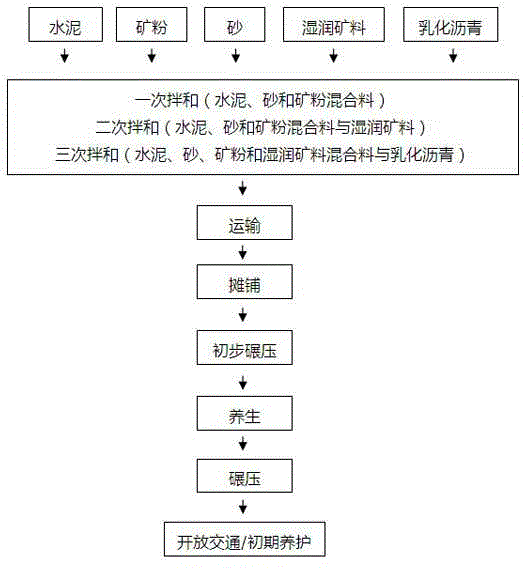

Method used

Image

Examples

Embodiment 1

[0116] In this embodiment, AC-20 type asphalt concrete graded gravel is selected to make a semi-flexible pavement with a thickness of 6 cm.

[0117] (1) Construction preparation

[0118] 1) Closed to traffic. Close traffic and control passing vehicles.

[0119] 2) Inspection of the underlying layer. Check and accept the lower bearing layer according to the specifications, and clean it.

[0120] 3) Measure the setting-out. Measure and set-out according to design requirements.

[0121] 4) Mix ratio design.

[0122] The design takes 100kg aggregate as an example. In 100kg of aggregates, 60kg of stones >4.75mm (10mm-20mm gravel: 4.75mm-9.5m gravel = 40:20), 10kg of 2.36mm-4.75mm stones, and ≤2.36mm stones (rice stone: Stone chips: mineral powder = 10:10:10) 30kg meets the specification requirements. If 10kg of 4.75mm-9.5mm stones are used instead of 2.36mm-4.75mm stones, in 100kg of aggregates, there are 70kg of coarse aggregates and 30kg of fine aggregates. Then, the mix...

Embodiment 2

[0143] In this embodiment, the SMA-16 asphalt mastic gravel gradation is selected to make a semi-flexible pavement with a thickness of 4 cm.

[0144] In this embodiment, except that the design of step 4) in the construction preparation stage (1) is different from that of embodiment 1, the rest of the steps are the same. Step 4) Specific content of the difference:

[0145] 4) Mix ratio design.

[0146] The design takes 100kg aggregate as an example. In 100kg of aggregates, 75kg of stones >4.75mm (10mm-16mm gravel: 4.75mm-9.5mm gravel = 45:30), 5kg of stones of 2.36mm-4.75mm, and materials of ≤2.36mm (rice stone: Stone chips: mineral powder = 2:8:10) 20kg meets the specification requirements. If 5kg of 1.18mm-2.36mm stones are used instead of 2.36mm-4.75mm stones, in 100kg of aggregates, there are 75kg of coarse aggregates and 25kg of fine aggregates. Then, the mixing ratio of fine aggregate becomes: rice stone: stone chips: mineral powder = 7:8:10.

[0147] The aggregate r...

Embodiment 3

[0154] In this embodiment, SMA-20 type asphalt mastic gravel gradation is selected to make a semi-flexible pavement with a thickness of 10 cm.

[0155] In this embodiment, except that the design of step 4) in the construction preparation stage (1) is different from that of embodiment 1, the rest of the steps are the same. Step 4) Specific content of the differences:

[0156] 4) Mix ratio design.

[0157] The design takes 100kg aggregate as an example. In 100kg of aggregates, 75kg of stones >4.75mm (10mm-20mm gravel: 4.75mm-9.5mm gravel = 50:25), 10kg of 2.36mm-4.75mm stones, ≤2.36mm materials (rice stone: Stone chips: mineral powder = 5:5:5) 15kg meets the specification requirements. If 10kg of 1.18mm-2.36mm stones are used instead of 2.36mm-4.75mm stones, in 100kg of aggregates, there are 75kg of coarse aggregates and 25kg of fine aggregates. Then, the mixing ratio of coarse aggregate is still: 10mm-20mm crushed stone: 4.75mm-9.5mm crushed stone = 50:25, and the mixing ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com