High-efficiency sodium chlorate electrolysis system

An electrolysis system and sodium chlorate technology, applied in the direction of electrolysis process, electrolysis components, electrode shape/type, etc., can solve problems such as restricting production capacity, and achieve the effects of saving floor space, easy maintenance, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

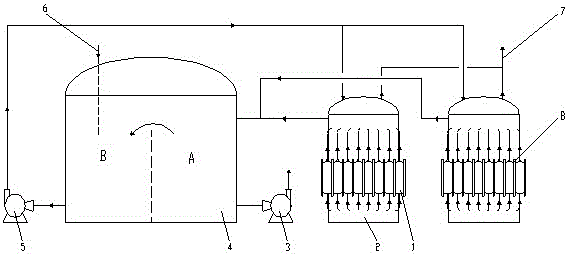

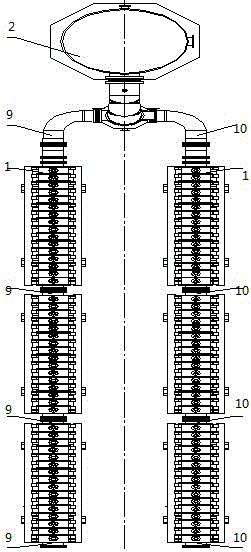

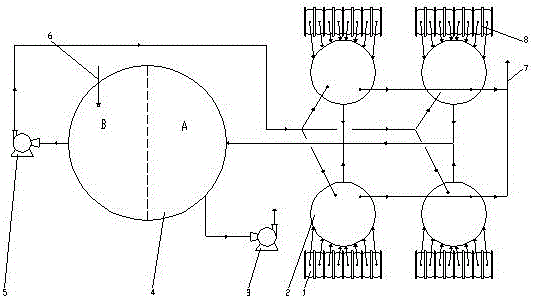

[0032] A high-efficiency sodium chlorate electrolysis system includes a circular electrolytic cell (1), a reactor (2), and a buffer tank (4). The inlet and outlet of each electrolytic cell (1) are separately connected to the reactor (2 ) connection, arranged symmetrically in two rows, the buffer tank is divided into two parts A and B, the A side of the buffer tank is connected to the reactor (2) through the pipeline, and the B side of the buffer tank is connected to the reactor (2) through the circulating pump (5) The top of the side of the buffer tank B is provided with a brine adding pipe (6), the bottom of the side of the buffer tank A is connected to the product delivery pump (3) through a pipeline, and the liquid outlet of the electrolytic tank (1) is a tapered structure. The top of the reactor (2) is provided with a hydrogen exhaust pipe (7). One reactor is equipped with 3 circular electrolyzers, and the anode area of each electrolyzer is 25m 2 .

[0033] A high-effic...

Embodiment 2

[0038] A high-efficiency sodium chlorate electrolysis system includes a circular electrolytic cell (1), a reactor (2), and a buffer tank (4). The inlet and outlet of each electrolytic cell (1) are separately connected to the reactor (2) through titanium tubes ) connection, arranged symmetrically in two rows, the buffer tank is divided into two parts A and B, the A side of the buffer tank is connected to the reactor (2) through the pipeline, and the B side of the buffer tank is connected to the reactor (2) through the circulating pump (5) The top of the side of the buffer tank B is provided with a brine adding pipe (6), the bottom of the side of the buffer tank A is connected to the product delivery pump (3) through a pipeline, and the liquid outlet of the electrolytic tank (1) is a tapered structure. The top of the reactor (2) is provided with a hydrogen exhaust pipe (7). One reactor is equipped with 6 circular electrolyzers, and the anode area of each electrolyzer is 28m 2 ...

Embodiment 3

[0044]A high-efficiency sodium chlorate electrolysis system includes a circular electrolytic cell (1), a reactor (2), and a buffer tank (4). The inlet and outlet of each electrolytic cell (1) are separately connected to the reactor (2 ) connection, arranged symmetrically in two rows, the buffer tank is divided into two parts A and B, the A side of the buffer tank is connected to the reactor (2) through the pipeline, and the B side of the buffer tank is connected to the reactor (2) through the circulating pump (5) The top of the side of the buffer tank B is provided with a brine adding pipe (6), the bottom of the side of the buffer tank A is connected to the product delivery pump (3) through a pipeline, and the liquid outlet of the electrolytic tank (1) is a tapered structure. The top of the reactor (2) is provided with a hydrogen exhaust pipe (7). One reactor is equipped with 8 elliptical electrolytic cells, and the anode area of each electrolytic cell is 30m 2 .

[0045] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com