Composite reaction chamber extension device used for growing electronic device and growing method

A technology of electronic devices and reaction chambers, which is applied in the field of compound reaction chamber epitaxy equipment and growth, can solve the problems of poor crystal quality and high dislocation density in the growth buffer layer, so as to solve the problems of poor crystal quality, improve comprehensive performance, and improve crystal quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

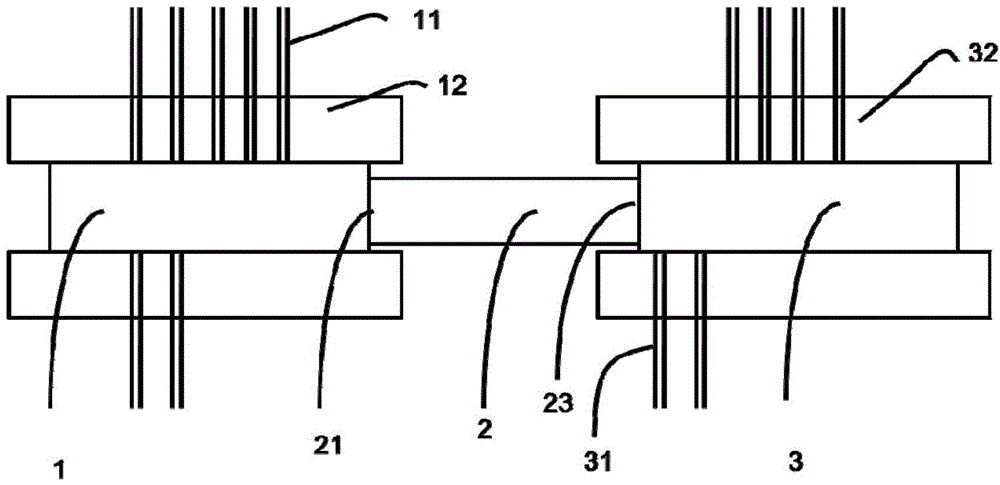

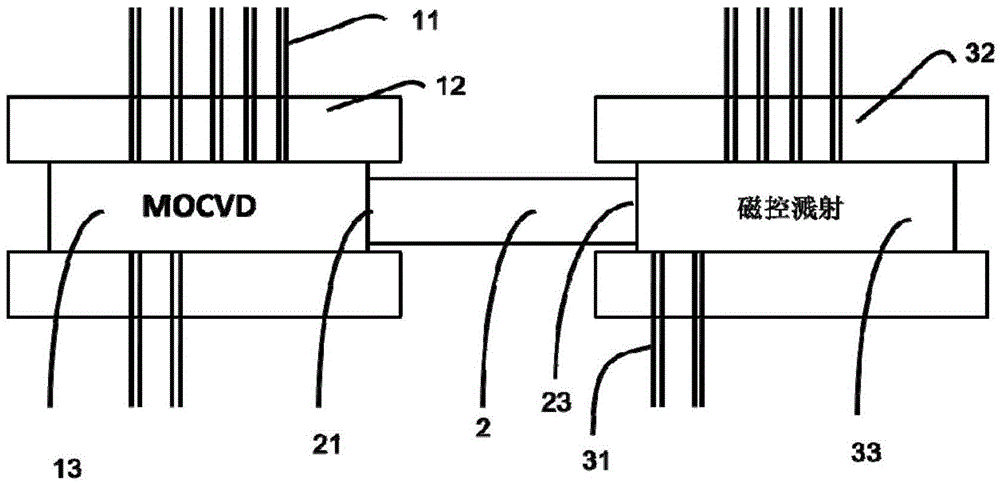

[0030] figure 1 The structural diagram of the composite reaction chamber deposition equipment provided by the present invention; figure 2 It is a top view of the composite reaction chamber deposition equipment structure of the present invention; wherein, 1 is a chemical reaction chamber; 11 is a source material delivery pipeline and a cooling water pipeline of the chemical reaction chamber; 12 is a cover plate of the chemical reaction chamber; 2 is The transfer chamber; 21 is the valve connecting the transfer chamber and the chemical reaction chamber; 22 is the manipulator of the transfer chamber; 23 is the valve connecting the transfer chamber and the physical reaction chamber; 3 is the physical reaction chamber; 31 is the source material of the physical reaction chamber Conveying pipeline and cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com