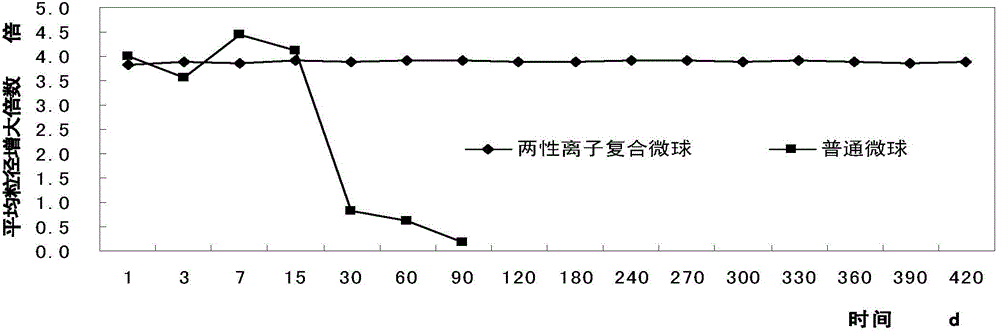

Amphoteric ion composite microsphere as well as preparation method and application thereof

A technology of composite microspheres and zwitterions, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of limited use and achieve the effect of improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Mix 57kg of deionized water and 3.7kg of sodium hydroxide evenly, lower the temperature below 20°C, add 5kg of monomeric acrylic acid, 5kg of 2-acrylamido-2-methylpropanesulfonic acid, acryloyloxyethyltrimethyl Ammonium chloride 7kg, N-methylolacrylamide 2kg, the temperature is always kept below 20°C, then add 0.1kg of crosslinking agent methylene acrylamide, filler bentonite 20kg, mix well, add initiator potassium persulfate 0.1 kg, anhydrous sodium sulfite 0.1kg, stir well. Place the system at 45°C to solidify the system. After complete reaction, place it in an environment of 65°C for aging for 2 hours, the polymerization reaction is completed, and then dry and pulverize.

Embodiment 2

[0019] Mix 50kg of deionized water and 5.5kg of sodium carbonate evenly, lower the temperature below 20°C, add 2kg of monomer acrylamide, 8kg of acrylic acid, 5kg of methacryloyloxyethyltrimethylammonium chloride, N,N-di 4kg of methacrylamide, the temperature is always kept below 20°C, then add 0.2kg of cross-linking agent methylene acrylamide, 25kg of filler high territory, mix well, add 0.2kg of initiator ammonium persulfate, 0.1kg of anhydrous sodium sulfite , stir well. Place the system at 45°C to solidify the system. After complete reaction, place it in an environment of 65°C for aging for 2 hours, the polymerization reaction is completed, and then dry and pulverize.

Embodiment 3

[0021] Mix 50kg of deionized water and 3.5kg of sodium hydroxide evenly, lower the temperature below 20°C, add 4kg of monomer acrylamide, 10kg of 2-acrylamido-2-methylpropanesulfonic acid, acryloyloxyethyl trimethyl Ammonium chloride 3kg, N-hydroxyethylacrylamide 2kg, the temperature is always kept below 20 ℃, then add 0.2kg of allyl methacrylate cross-linking agent, heavy calcium filler 27kg, mix well, add the initiator over Ammonium sulfate 0.2kg, anhydrous sodium sulfite 0.1kg, stir well. Place the system at 45°C to solidify the system. After complete reaction, place it in an environment of 65°C for aging for 2 hours, the polymerization reaction is completed, and then dry and pulverize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com