Scaffold and construction method based on coke oven resistance wall

A scaffolding and resistance wall technology, applied in the directions of building, building structure, housing structure support, etc., can solve the problems of low wind resistance safety, poor stability, less diagonal braces, etc., and achieve high main structure strength, improve strength, spacing small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

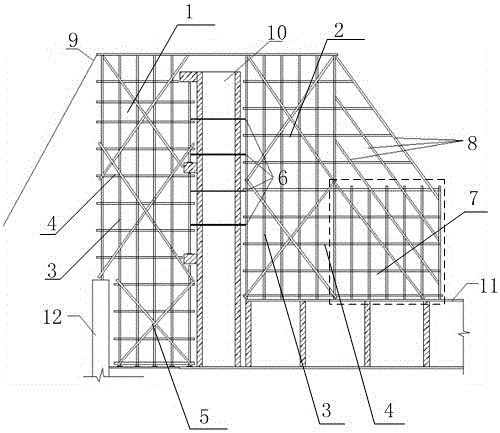

[0029] Such as figure 1 As shown, the present embodiment provides a scaffold based on the coke oven resistance wall. The scaffold mainly includes two frames, namely the first scaffold 1 and the second scaffold 2, which are respectively located on the left and right sides of the coke oven resistance wall. Specifically, the first scaffolding is located on the left side of the coke oven resistance wall, between the coke oven resistance wall and the coke platform retaining wall, the second scaffolding is located on the right side of the coke oven resistance wall, further, it is located above the bed. Both the first scaffold 1 and the second scaffold 2 are composed of six vertical rows of columns 3 arranged with gaps, a number of horizontal span columns 4 arranged with transverse gaps, and fastening columns 3 and transverse span columns 4 "X"-shaped support columns 5. Further, the first scaffold 1 and the second scaffold 2 are both six-row four-step scaffolds, and the structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com