A kind of composite anaerobic membrane bioreactor and its application

An anaerobic membrane biology and reactor technology, which is applied in anaerobic digestion treatment, biological treatment equipment, biological water/sewage treatment, etc., can solve the problems of increasing water production costs, serious problems, power energy consumption, etc., and improve purification efficiency , Avoid membrane fouling and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

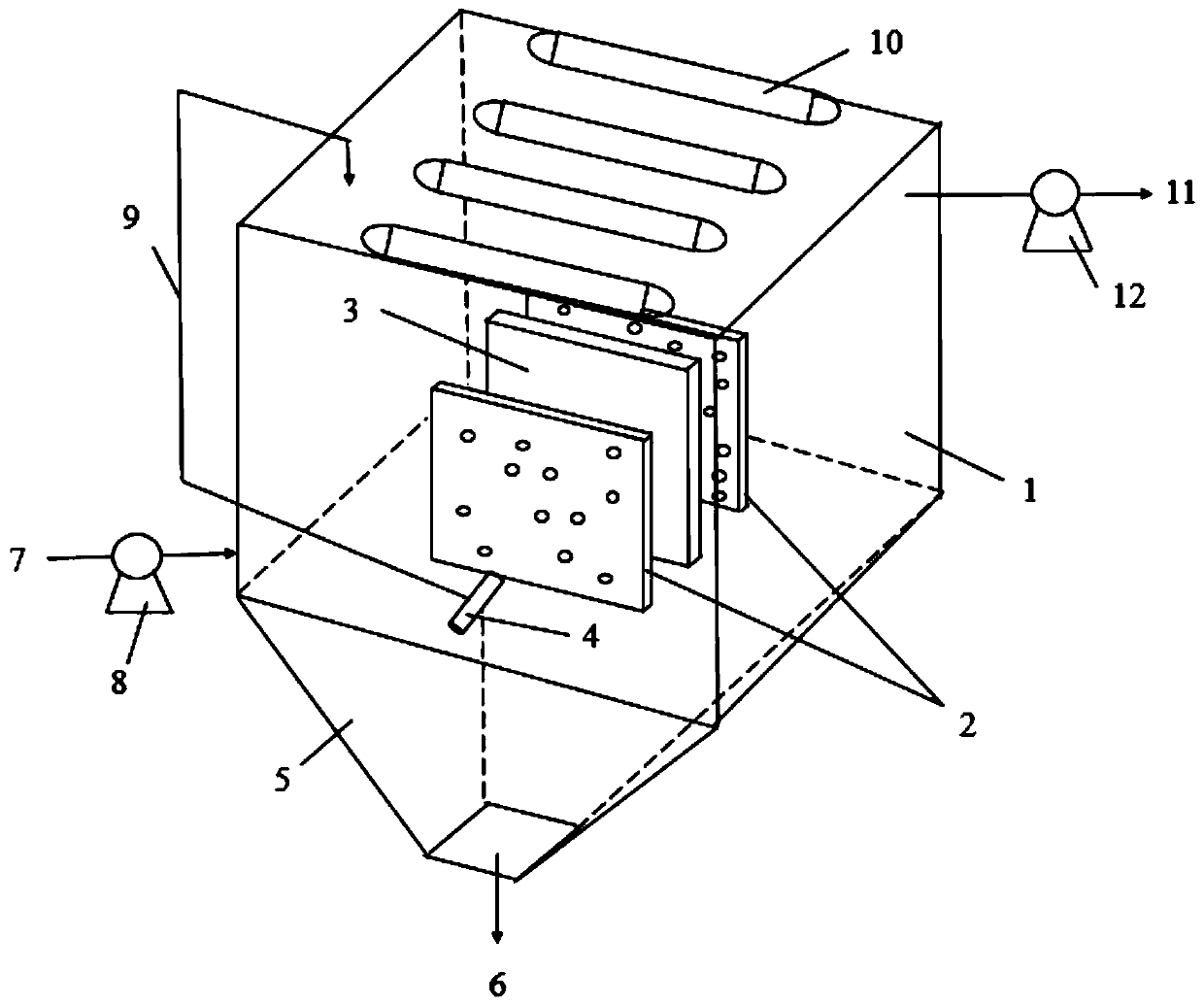

[0028] Such as figure 1 As shown, a composite anaerobic membrane bioreactor includes an anaerobic membrane system, a near-infrared light irradiation system, an aeration system, a sludge system, an inflow and outflow system, and a reactor main shell 1 . The main body shell 1 of the reactor is made of PVC material, the upper part of the main frame is cuboid, and the size is 30cm, 35cm, 50cm. 2 , the pore size is 0.5um, the maximum operating flow rate of the membrane is controlled at 2L / h per square meter, and a PVC support plate 3 is set between the two membranes.

[0029] A near-infrared LED lamp 10 with a wavelength of 850nm and a power of 2W is installed on the top of the reactor as an energy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com