Method for disposing filter cake of vertical leaf filter

A leaf filter filter cake and disposal method technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of increasing the workload of the red mud separation and washing process, the adverse effects of the desiliconization and dissolution process, and the loss of useful components, and reduce the The amount of crude liquid and the content of suspended matter, the effect of reducing the amount of circulation of the crude liquid and reducing the working load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

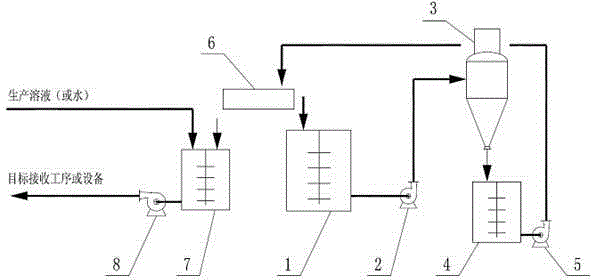

[0021] As shown in the figure, a method for disposing of the filter cake of the vertical leaf filter of the present invention, the method of disposing of the filter cake of the vertical leaf filter comprises the following steps: sending the filter cake produced after filtering the crude liquid to the solid-liquid separation equipment 6 Concentrate to reduce the liquid content of the filter cake, and then slurry the filter cake and transport it to the target receiving process for recycling.

[0022] Sending the filter cake produced after crude liquid filtration to solid-liquid separation equipment for concentration refers to using one of the vertical disc filter, flat disc filter, filter press, centrifuge or high-pressure filter to process the fine filter cake. concentrate.

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com