Oxyhydrogen scrubber used in water electrolysis for hydrogen production

A technology of scrubber and water electrolysis, which is applied in the field of hydrogen-oxygen scrubber, can solve the problems of gas quality, purification treatment and analysis instrument impact, electrolysis power consumption increase, resource waste, etc., to reduce temperature, reduce burden, and reduce alkali loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

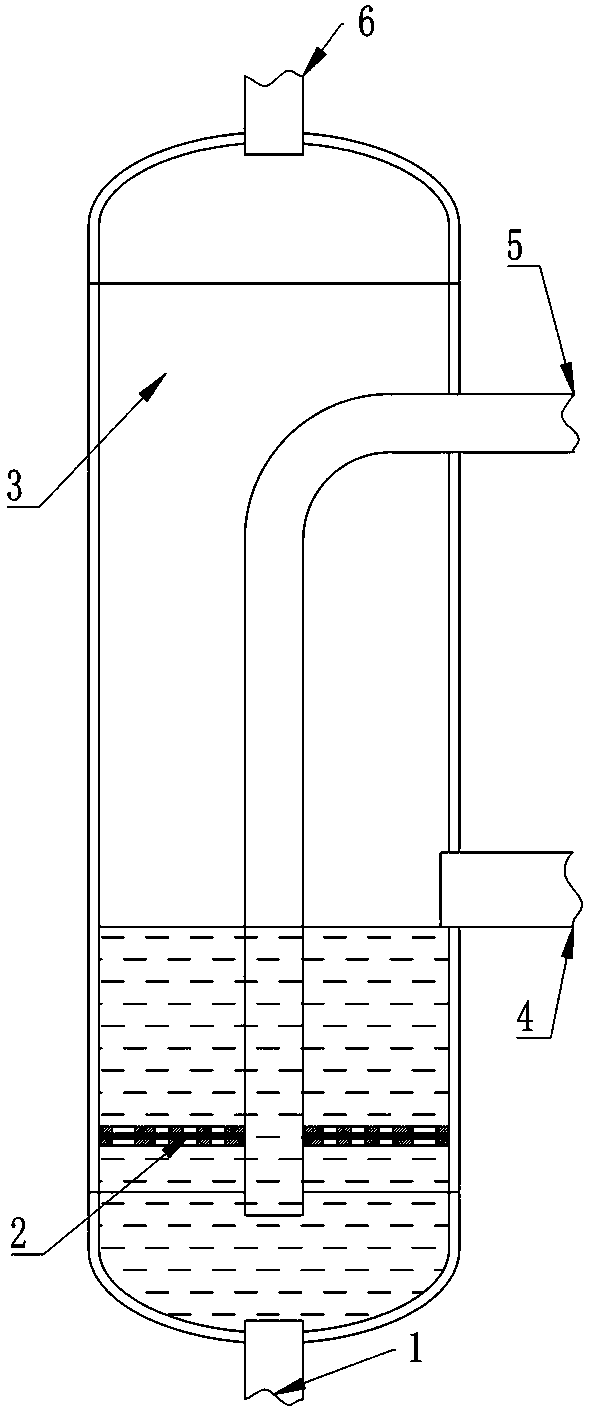

[0010] Such as figure 1 As shown, the hydrogen-oxygen scrubber for water electrolysis hydrogen production is installed between the separator and the gas cooler. In particular, the main body of the hydrogen-oxygen scrubber is a washing cabin 3 filled with electrolytic raw water. 3. An air intake pipe 5 is pierced on the side wall. One end of the air intake pipe 5 is connected to the exhaust port of the separator, and the other end of the air intake pipe 5 extends below the liquid level of the electrolytic raw material water in the washing cabin 3; the washing cabin 3 The top is provided with an air outlet 6.

[0011] In order to facilitate the alkali replenishment of the separator, the side wall 3 of the washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com