Hydraulic machine for fine blanking of sheet metal

A technology of precision blanking and hydraulic press, applied in the field of forging machinery, can solve the problem that blanking parts cannot meet the requirements of surface finish or dimensional accuracy, cannot meet the requirements of high-precision fine punching die, and the clamping force of upper push cylinder and lower jack cylinder Problems such as different axes can avoid roughening or tearing of the punching surface, compact structure, and reduce the cost of waste materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

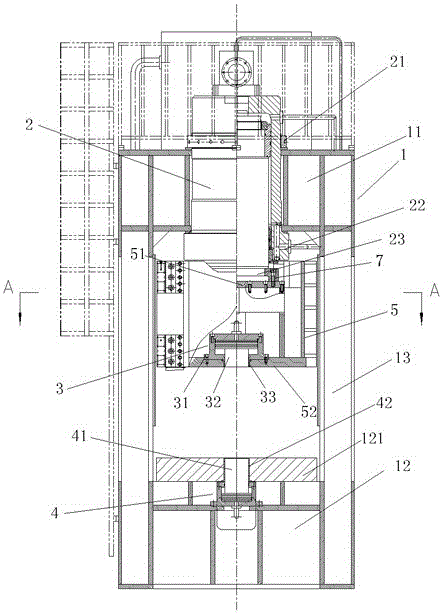

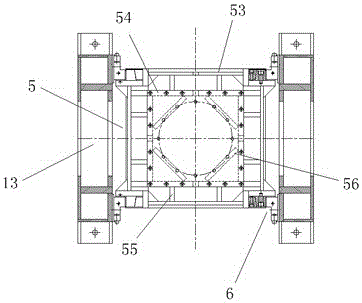

[0017] like figure 1 and figure 2 As shown, the present invention comprises fuselage 1, main oil cylinder 2, counter pressure cylinder 3, ring gear cylinder 4 and slide block 5, and fuselage 1 is the closed fuselage of frame structure, comprises upper beam 11, lower workbench 12 and The side arms 13 located on both sides of the upper beam 11 and the lower workbench 12, such a structure makes the radius λ≤1 / 20000 of the fuselage 1 the height of the fuselage, which is much smaller than the radius λ≤1 of the existing fine blanking hydraulic press The height of the fuselage is / 6000, and the rigidity of the fuselage 1 is more than 3 times that of the existing fuselage, which ensures the running accuracy of the slider 5, thereby greatly improving the quality of the precision blanking parts. The ring gear cylinder 4 is arranged in the lower workbench 12, the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com