Electric tool and torsion switching device thereof

A technology for switching devices and electric tools, which is applied in the direction of portable motorized devices, manufacturing tools, etc., can solve problems such as inability to jump gears, achieve a large error tolerance range, and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

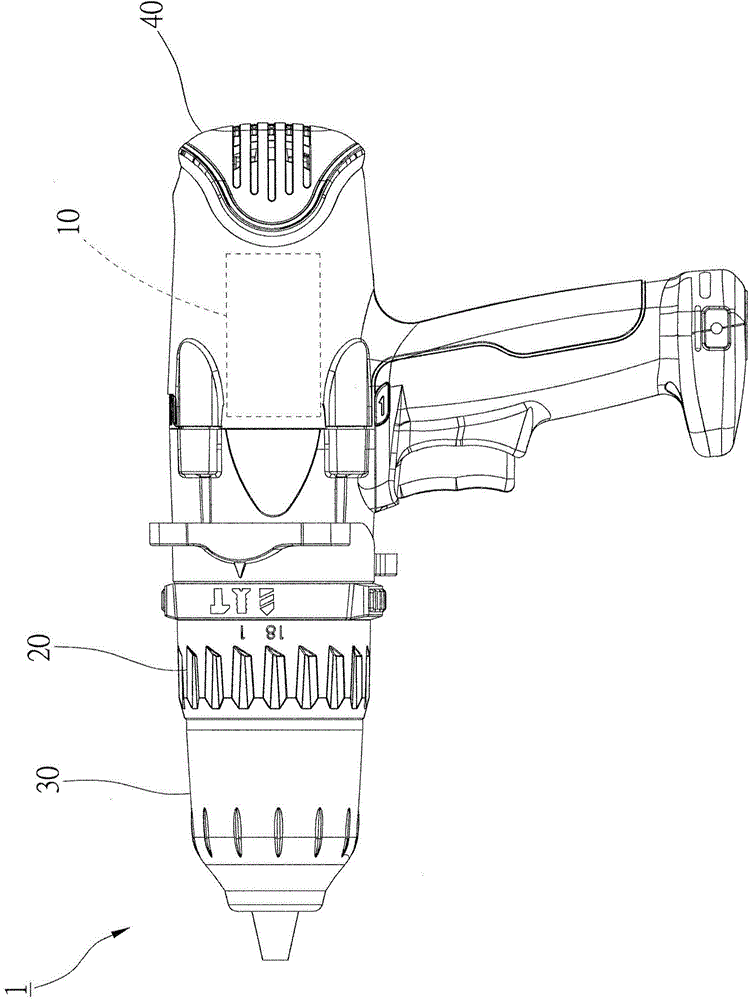

[0056] In order to illustrate the present invention more clearly, preferred embodiments are given together with diagrams in detail as follows. figure 1 It is a side view of an electric tool according to an embodiment of the present invention. The electric tool 1 includes an electric motor 10 , a torque switching device 20 , a chuck 30 and a housing 40 . Parts of the electric motor 10 and the torque switching device 20 are disposed in the casing 40 .

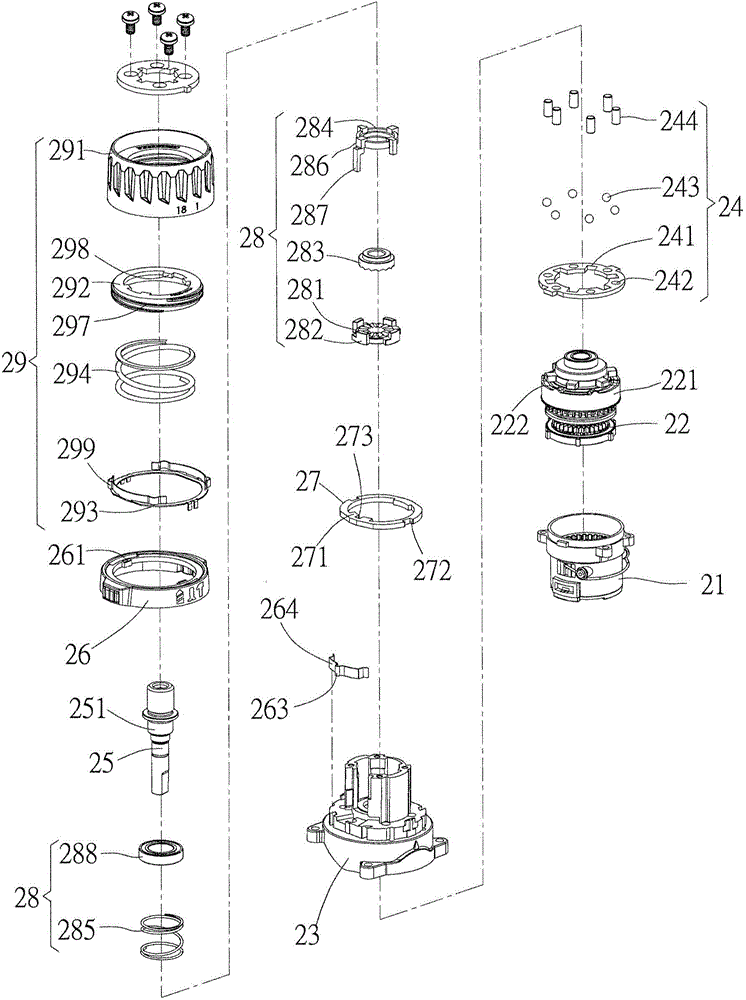

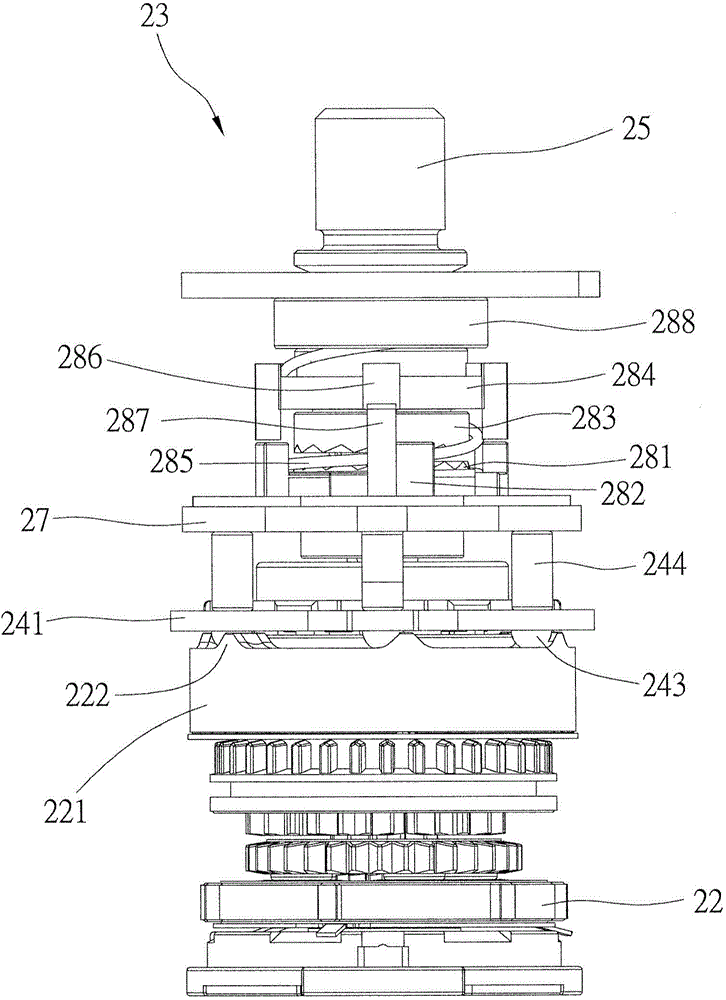

[0057] figure 2 The shown torque switching device 20 includes a gear box 21, a speed change gear set 22, a base 23, a jump gear mechanism 24, a main shaft 25, a switching button 26, a switching ring 27, an impact mechanism 28, a Torque adjustment mechanism 29.

[0058] The speed change gear set 22 is disposed in the gear box 21 , and the output shaft (not shown) of the electric motor 10 is connected to the speed change gear set 22 of the torque switching device 20 . One end of the spindle 25 is connected to the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com