A kind of strong plate stress hole cutting machine and using method

A cutting machine and stress technology, applied in the field of hard plate stress hole cutting machines, can solve the problems of poor control of the radius R of the stress hole, affecting the progress of the project, poor quality of the stress hole, etc., to achieve stable and excellent cutting quality and reduce labor intensity. , The effect of fast mechanical cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

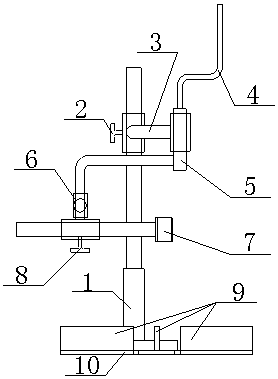

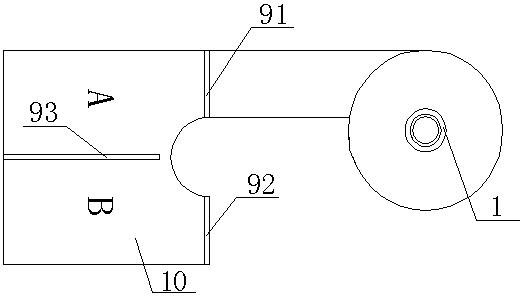

[0032] see now figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a stress hole cutting machine for stiffened plates according to an embodiment of the present invention, figure 2 for figure 1 side view. As shown in the figure, the center of the base 1 is vertically provided with a vertical pole; a peripheral edge of the base 1 is fixedly connected to a rectangular steel plate operating platform 10 with a gap, and the middle part of the operating platform is provided with a long strip with a semicircular head. , A zone and B zone are set up on both sides of the semicircular head;

[0033] The two ends of the pole 3 are provided with sleeves, one end of which is sleeved on the pole, and is fastened on the pole by the first adjusting bolt 2, and the pole 3 is perpendicular to the pole; the pole 3 Can move up and down on the pole to adjust the height.

[0034] The rotating shaft 5 is fitted in the sleeve at the other end of the pole 3, the upper part ...

Embodiment 2

[0037] A method for using a stress hole cutting tool in a stiff plate, characterized in that it comprises the following steps:

[0038] a. Put the stiff plate stress hole cutting machine on a platform with a certain height from the ground, fix the air supply device and the cutting nozzle on the branch pipe 6 for installing the air supply device and the branch pipe 7 for installing the cutting nozzle respectively, and then The A area and the B area of the operating platform 10 each place a stiff plate with a stress hole to be processed; the first dividing plate 91 and the second dividing plate 92 are arranged on both sides of the semicircular notch, and the first dividing plate 91 and the second dividing plate 92 Arranged in a straight line, the third partition 93 is set on the boundary line between the A area and the B area, and is perpendicular to the line connecting the first partition 91 and the second partition 92, so as to ensure that the stiffeners are placed vertically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com