Reciprocating type spraying flushing machine for gear shaft of gearbox

A gearbox and gear shaft technology, applied in the field of reciprocating gearbox gear shaft jet washing machines, can solve the problems of the gear shaft being difficult to meet the needs of use, the cleaning effect is not ideal, the cleaning efficiency is low, etc. Ingenious design and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and embodiments:

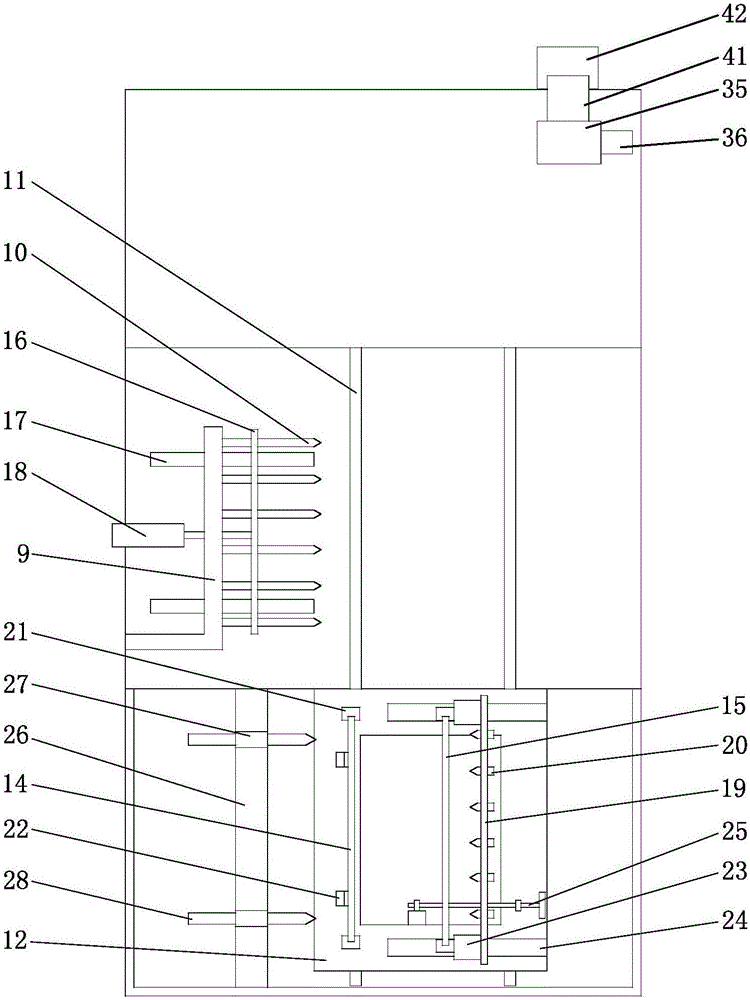

[0028] Such as figure 1 , figure 2 , image 3 As shown, an operation compartment 2 is provided at the upper part of the front end of the bed 1, and the upper end of the operation compartment 2 is open. A cleaning bin 3 is arranged above the middle of the bed 1, and the front end of the cleaning bin 3 is provided with an inlet and outlet 4. The upper part of the inlet and outlet 4 is covered by a fixed door 29. A movable door 30 is provided in front of the fixed door 29. The two ends of the movable door 30 are located in corresponding guide chutes. The middle of the top of the movable door 30 is connected to the vertical cylinder 31. The piston rod of the vertical cylinder 31 is fixed on the top of the front end of the cleaning chamber 3. Under the action of the vertical cylinder 31, the movable door 30 can be raised or lowered to open or close the opening at the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com