Novel compound impact type gravel crusher

An impact and crusher technology, applied in grain processing and other directions, to achieve the effects of optimizing material grading, reducing wear and improving the crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

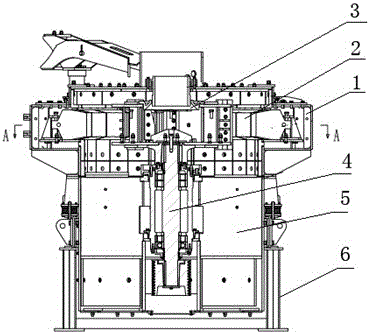

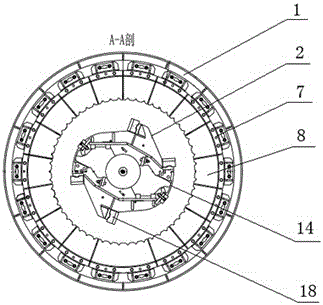

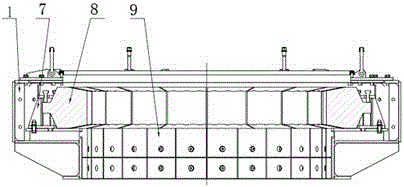

[0012] Provide the specific embodiment of the present invention below in conjunction with accompanying drawing as follows:

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a new composite impact sandstone crusher according to the present invention is mainly composed of a crushing cavity and an impeller; wherein: the crushing cavity is composed of a crushing cavity 1, an impact plate frame 7, an impact plate 8, and a lower guard plate 9 Composition; the inner edge of the impact plate 8 is tooth-shaped, and the outer edge of the impact plate 8 is installed on the impact plate frame 7; several impact plates 8 are fixed in the crushing chamber 1 through the impact plate frame 7 with connecting bolts to form a circular ring Toothed crushing surface; the impact plate 8 is the main wear part of the crushing work, and it is made of high-chromium alloy with excellent wear resistance. Adjust the central area of the center area to a certain distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com