An integral button part for aviation circuit breaker

A circuit breaker and button technology, which is applied in the field of product molding and processing, can solve problems such as intolerance to organic solvents, low assembly efficiency, and low part pass rate, and achieve the effects of ensuring mechanical strength, high processing efficiency, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

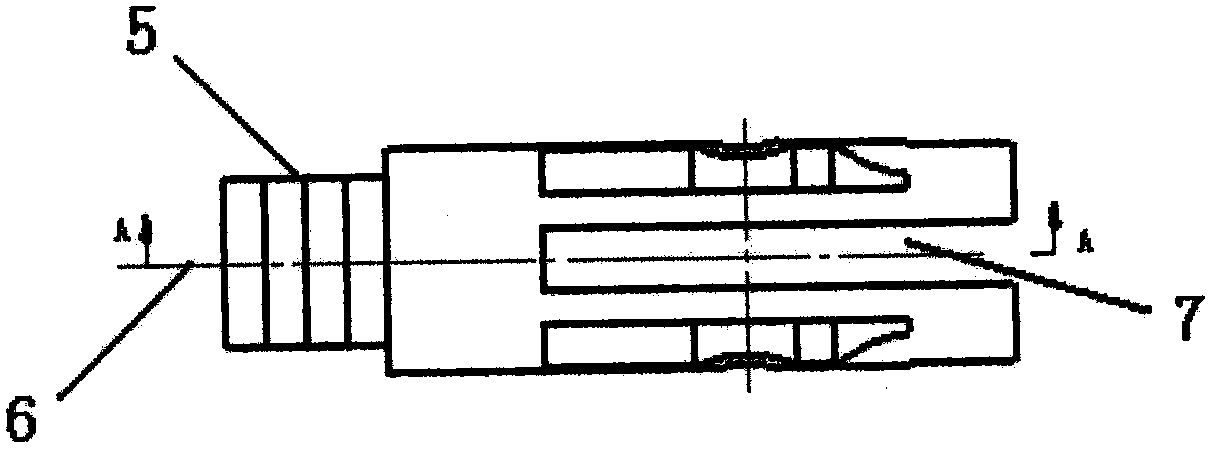

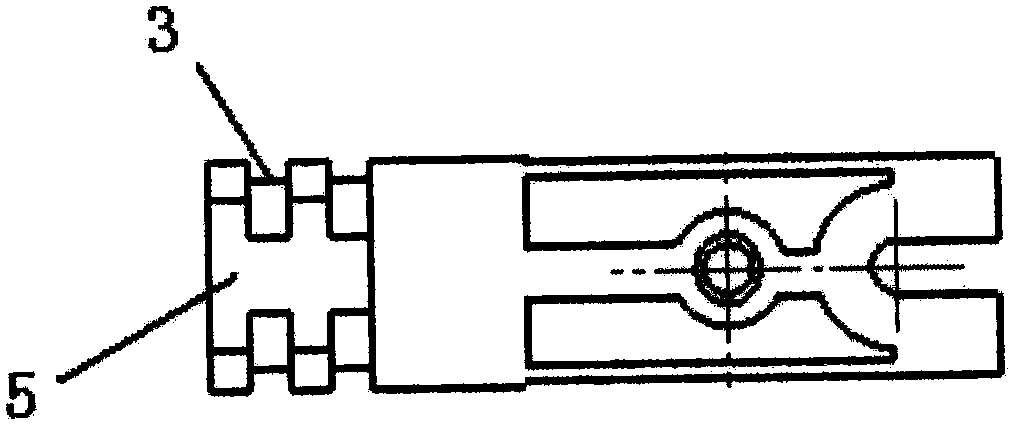

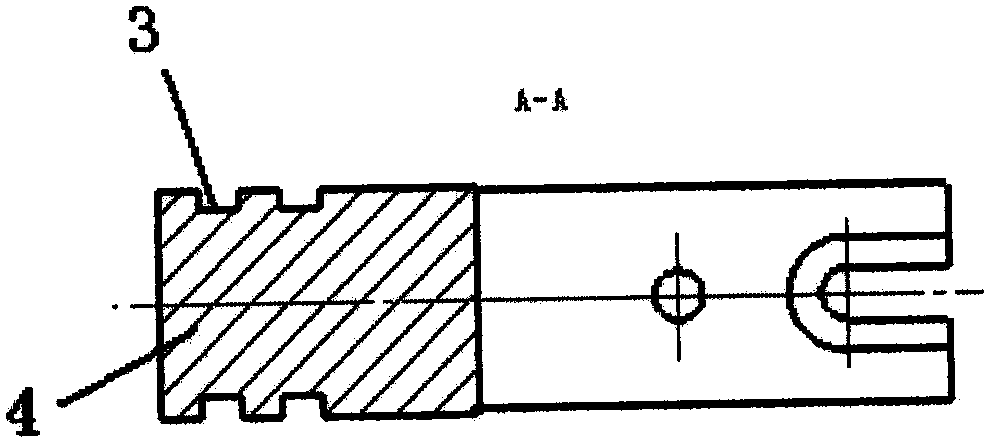

[0019] See attached Figure 1~5 As shown, an integral button for an aviation circuit breaker, including a bracket 2 and a button 1, is characterized in that:

[0020] (1) Bracket 2 is integrally formed by ZLD-105 aluminum alloy. Two annular grooves 3 are processed on the circumferential surface of the connecting end 4 of bracket 2 and button 1. The width of the annular groove 3 is 1 mm and the depth is 0.5 mm. , the distance between the two annular grooves 3 is 1mm. On the connecting end 4, two parallel step surfaces 5 are processed along the direction of the central axis 6 of the bracket 2. The two step surfaces 5 are symmetrical with respect to the central axis 6. The two steps The surface 5 is parallel to the strip-shaped movable piece installation groove 7 of the bracket 2, and the maximum distance between the stepped su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com