Release film for ceramic green sheet manufacturing process

A ceramic green sheet and peeling film technology, which is applied in the photoplate making process of the patterned surface, photosensitive material processing, instruments, etc., can solve the problems of easy charging of static electricity, and achieve the effect of excellent peeling property and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0087] Into a reactor equipped with a stirrer, a reflux cooler, a dropping funnel, and a thermometer, 100 parts by mass of hexamethylene diisocyanate (in terms of solid content; the same applies hereinafter) as polyvalent isocyanate (a2), dimethyl organic poly Siloxane (a3) (manufactured by Chisso Corporation, product name "SILAPLANE FMDA11", number average molecular weight 1000; has the structure shown in general formula (3), R in general formula (3) 1 for -OH, R 2 for -(CH 2 ) 3 OCH 2 CH 2 -, R 3 for -CH 2 CH 3 . The structure of the same product is the same below. ) 300 parts by mass and 400 parts by mass of methyl ethyl ketone were heated up to 85° C. and kept for 7 hours to react to obtain a reactant.

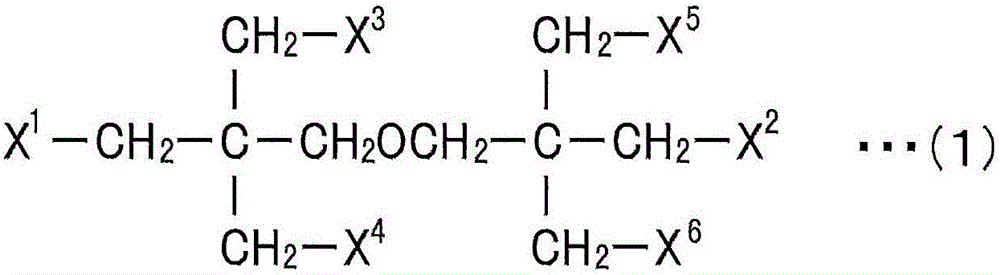

[0088] In another reactor having the same equipment as above, a mixture of dipentaerythritol hexaacrylate and dipentaerythritol pentaacrylate (manufactured by TOAGOSEI CO., LTD., product name "M-400," containing 50% by mass of dipentaerythritol pentaacrylate; 2...

manufacture example 2

[0090] In a reactor equipped with a stirrer, a reflux cooler, a dropping funnel, and a thermometer, 100 parts by mass of hexamethylene diisocyanate as a polyvalent isocyanate (a2), dimethylorganopolysiloxane (a3) (Chisso Corporation Manufactured, product name "SILAPLANE FM DA11", number average molecular weight (1000) 300 parts by mass, and methyl ethyl ketone 400 parts by mass, heated up to 85° C. and kept for 7 hours to react to obtain a reactant.

[0091] In another reactor having the same equipment as above, a mixture of dipentaerythritol hexaacrylate and dipentaerythritol pentaacrylate (manufactured by TOAGOSEI CO., LTD., product name "M-400;" the structure represented by the general formula (1)) 258 parts by mass, 40 parts by mass of the solid content of the reactant obtained above, and 258 parts by mass of methyl ethyl ketone, heated to 85° C. and kept for 7 hours to make it It reacted, and the disappearance of an isocyanate group was confirmed by IR measurement, and ...

manufacture example 3

[0093] In a reactor equipped with a stirrer, a reflux cooler, a dropping funnel, and a thermometer, 100 parts by mass of hexamethylene diisocyanate as a polyvalent isocyanate (a2), dimethylorganopolysiloxane (a3) (Chisso Corporation Manufacture, product name " SILAPLANE FM DA21 ", number average molecular weight is 5000; Has the structure shown in general formula (3), the R in general formula (3) 1 for -OH, R 2 for -(CH 2 ) 3 OCH 2 CH 2 -, R 3 for -CH 2 CH 3 . ) 1488 parts by mass and 1588 parts by mass of methyl ethyl ketone were heated up to 85° C. and kept for 7 hours to react to obtain a reactant.

[0094] In another reactor having the same equipment as above, a mixture of dipentaerythritol hexaacrylate and dipentaerythritol pentaacrylate (manufactured by TOAGOSEI CO., LTD., product name "M-400;" the structure represented by the general formula (1)) 289 parts by mass, 10 parts by mass of the solid content of the reactant obtained above, and 289 parts by mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com