A high-safety lithium manganese iron phosphate battery

A lithium manganese iron phosphate, high-safety technology, applied in the direction of battery electrodes, secondary batteries, secondary battery repair/maintenance, etc. poor lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

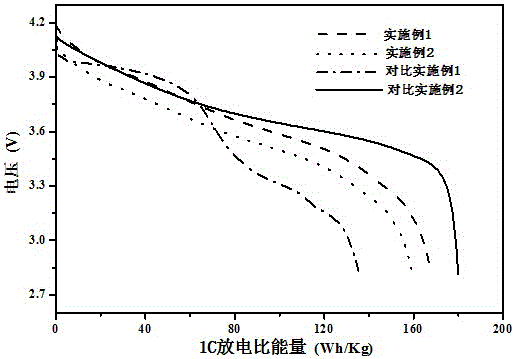

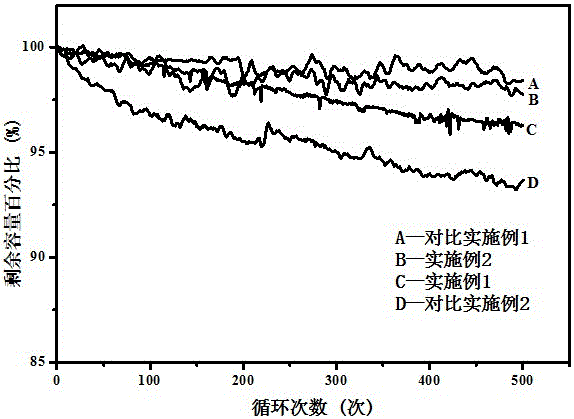

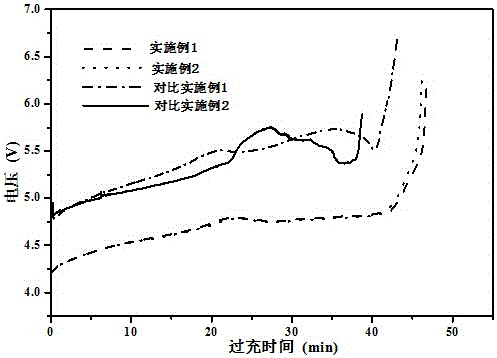

Embodiment 1

[0033] In this embodiment, the laminated flexible packaging battery technology is used for production.

[0034] In this embodiment, the positive electrode active material content is 20 wt% of lithium manganese iron phosphate and 80 wt% of nickel cobalt lithium manganese oxide.

[0035] The manufacturing method of positive pole piece in the present embodiment is:

[0036] 1) Material baking: Weigh lithium iron manganese phosphate, nickel cobalt lithium manganate, polyvinylidene fluoride, conductive carbon black and graphene solutions according to 19wt%: 75.3wt%: 3wt%: 2wt%: 0.7wt%. The lithium manganese iron phosphate, lithium nickel cobalt manganese oxide and conductive carbon black powder were vacuum-baked at 120°C for 8 hours, and the polyvinylidene fluoride (molecular weight 1 million to 1.1 million) powder was vacuum-baked at 80°C. Bake for 4 hours, use a cassette furnace to measure the moisture content and cool to below 40°C for later use.

[0037] 2) Glue preparation: ...

Embodiment 2

[0047] In this embodiment, the laminated flexible packaging battery technology is used for production.

[0048] In this embodiment, the positive electrode active material content is 30 wt% of lithium manganese iron phosphate and 70 wt% of nickel cobalt lithium manganese oxide.

[0049] The manufacturing method of positive pole piece in the present embodiment is:

[0050] 1) Material baking: Weigh lithium iron manganese phosphate, nickel cobalt lithium manganate, polyvinylidene fluoride, conductive carbon black and graphene solutions according to 28.2wt%: 65.8wt%: 3wt%: 2wt%: 1wt%. The lithium manganese iron phosphate, lithium nickel cobalt manganese oxide and conductive carbon black powder were vacuum-baked at 120°C for 8 hours, and the polyvinylidene fluoride (molecular weight 1 million to 1.1 million) powder was vacuum-baked at 80°C. Bake for 4 hours, use a cassette furnace to measure the moisture content and cool to below 40°C for later use.

[0051] 2) Glue preparation: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com