Flexible solar cell packaging multilayer composite film and application thereof

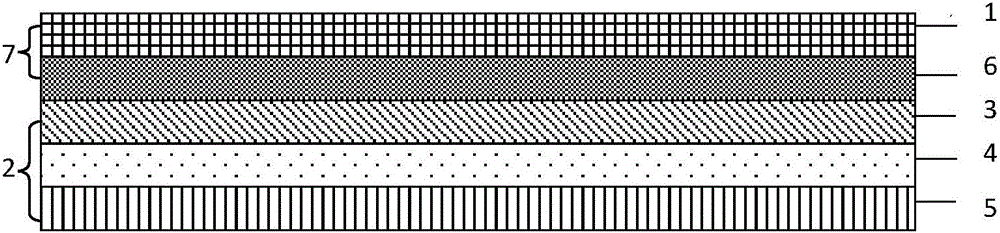

A solar cell and multi-layer composite technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large packaging film thickness, low product yield rate, soft and difficult to spread, etc., to achieve improved yield rate and good water vapor barrier , the effect of excellent transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] As the material of the base film layer, an ETFE film (Asahi Glass 50N1250DSC) with a thickness of 50 μm and a light transmittance of 92% is selected, and an acrylate compound primer (CN201110133880.6) is coated on its surface using a metal micro-gravure coater on the well. The unwinding tension is 50N~150N, the coating speed is 10~15m / min, the roller speed ratio is 75%, the drying path temperature is controlled at 40℃ / 40℃ / 60℃ / 80℃ / 60℃, and the winding tension is 100N~150N. Finally, an undercoat layer with a film thickness of 1.5 μm was formed.

[0056] Use PECVD coating device at film forming pressure 1.5Pa, power frequency 90kHz, use hexamethyldisiloxane (HMDSO) and oxygen as reaction raw material gas, two gas flow ratio HMDSO:O 2 =10:1, the vehicle speed is 2m / min, the coating is divided into 3 times, and the power used for the three times is 1.5kW / 2.2kW / 2.6kW respectively. A gas barrier layer with a thickness of 300 nm was obtained.

[0057] The protective film mate...

Embodiment 2

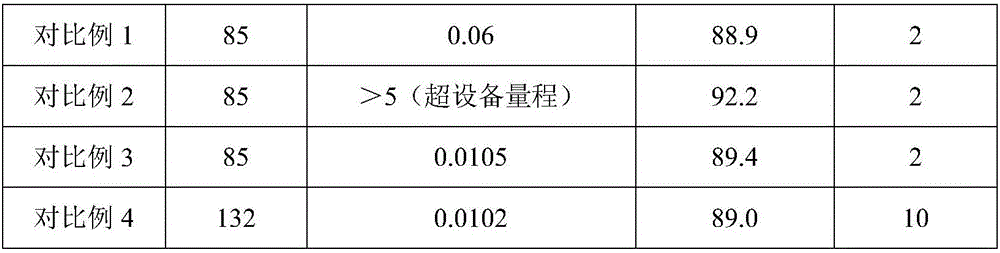

[0059] Others are the same as in Example 1, the base material is an ETFE film with a thickness of 25 μm and a light transmittance of 91%, the preparation process of the undercoat and the gas barrier layer is unchanged, and the water vapor transmission rate and light transmittance performance of the final product are shown in Table 1 shown.

Embodiment 3

[0061] Others are the same as in Example 1, the substrate is a PI film with a thickness of 75 μm and a light transmittance of 85%, the preparation process of the primer layer and the gas barrier layer remains unchanged, and the water vapor transmission rate and light transmittance performance of the final product are shown in Table 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com