Working electrode of three-dimensional dye-sensitized solar cell, and preparation method of working electrode

A technology for solar cells and dye sensitization, which is applied in the field of three-dimensional dye-sensitized solar cell working electrodes and the preparation thereof, can solve the problems of easy recombination of electron holes, low dye adsorption rate, small effective area, etc. High repeatability and the effect of increasing the adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention is described in further detail:

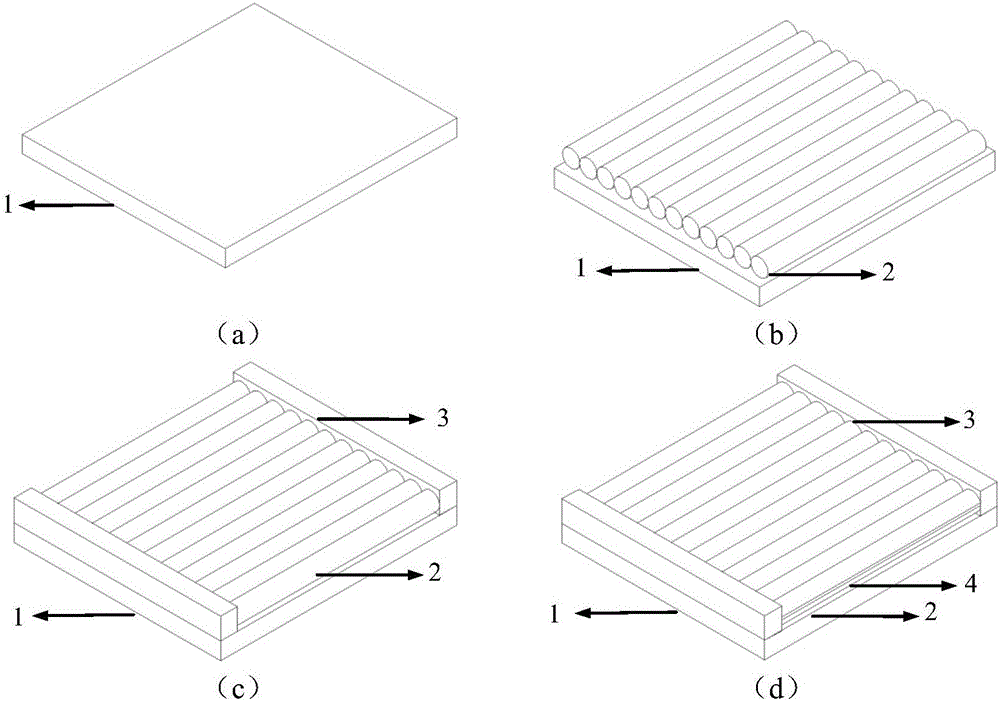

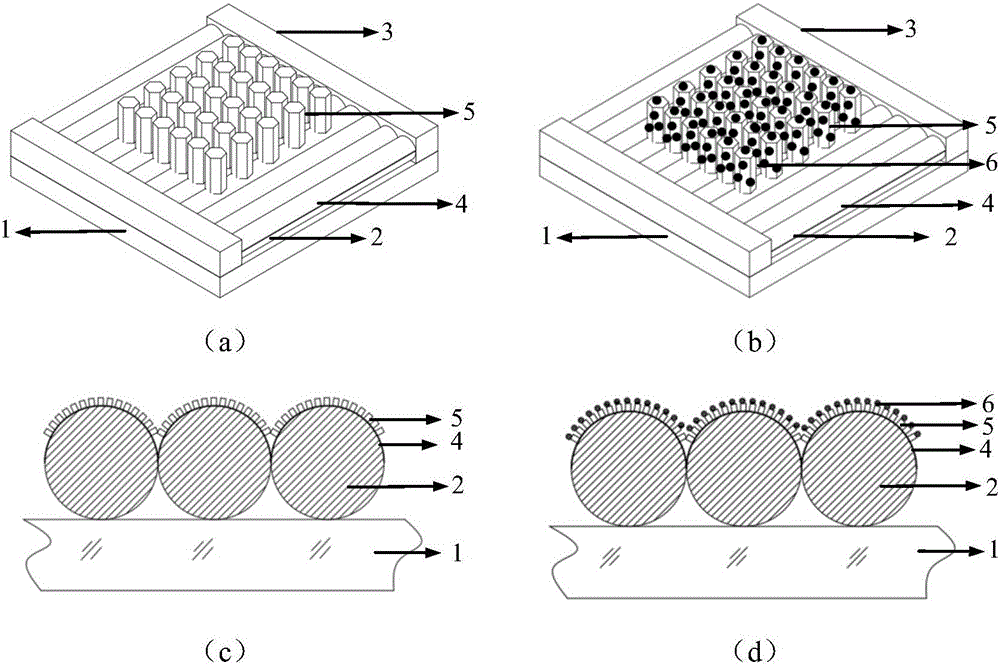

[0038] see figure 1, 2, the fiber cores 2 are closely arranged and fixed on the glass substrate, and a layer of 80nm thick indium tin oxide conductive layer 4 is sputtered on it to form a three-dimensional semi-cylindrical micron-scale substrate; based on the water bath method, the three-dimensional semi-cylindrical ZnO nanowires 5 were synthesized on a micron-scale substrate to obtain a three-dimensional semi-cylindrical cross-scale structure array; the ruthenium complex dye 6 was physically adsorbed and immobilized on the surface of the above-mentioned three-dimensional cross-scale structure array, and a three-dimensional cross-scale structure array based on Working electrodes of dye-sensitized solar cells. The length of the glass substrate is 3cm, the width is 3cm, and the thickness is 1.1cm; the length of the optical fiber core 2 is 3cm, and the diameter is Φ125μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com