Composite material laminate non-probability reliability double-level optimization method

A technology of composite material layer and optimization method, which is applied in the field of optimal design of composite material laminate structure, and can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

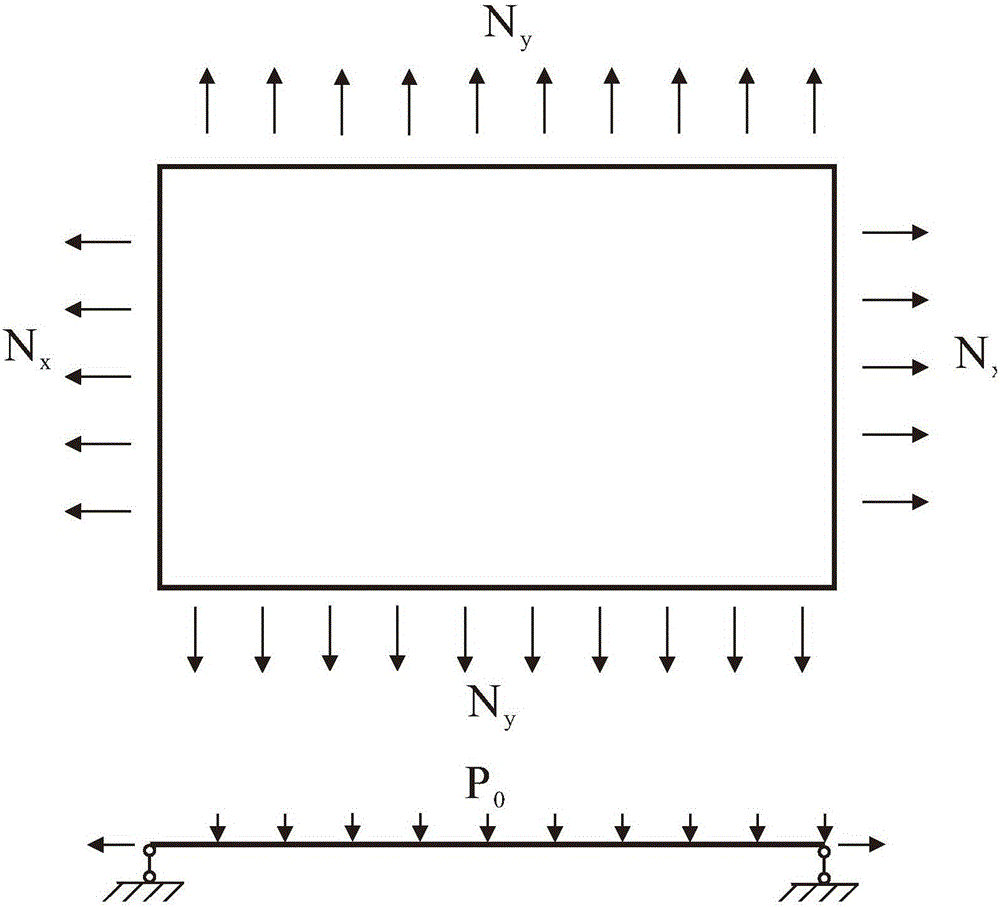

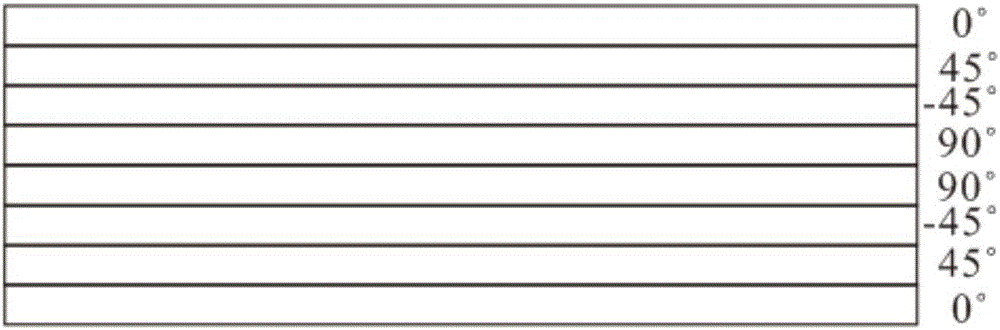

[0116] In order to understand more fully the characteristics of the invention and its applicability to engineering practice, the present invention aims at such as figure 2 In-plane tensile load N x and N y and the out-of-plane pressure P 0 The laminates are optimized based on reliability. Laminate layering method is [0 / 45 / -45 / 90] 4s . The in-plane dimension of the laminate is a×b=(20*12.5)cm 2 , the thickness of the single-layer board is 0.125mm, so the total thickness of the laminated board is 0.125mm×32=4mm. Table 1 gives the uncertainty information of the strength parameters of the rectangular plate structure in the example, and Table 2 gives the uncertainty information of the elastic parameters and external loads of the rectangular plate structure in the example.

[0117] Table 1

[0118]

[0119] Table 2

[0120]

[0121] This embodiment employs, reliability applications such as Figure 4 The strength reliability of the shown Tsai-Wu interval is obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com