Enterprise energy efficiency management system and management and control method therefor

An energy efficiency management and enterprise technology, applied in the field of management systems, can solve problems such as inability to achieve scientific, reasonable, and precise command, reduced efficiency, and increased operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

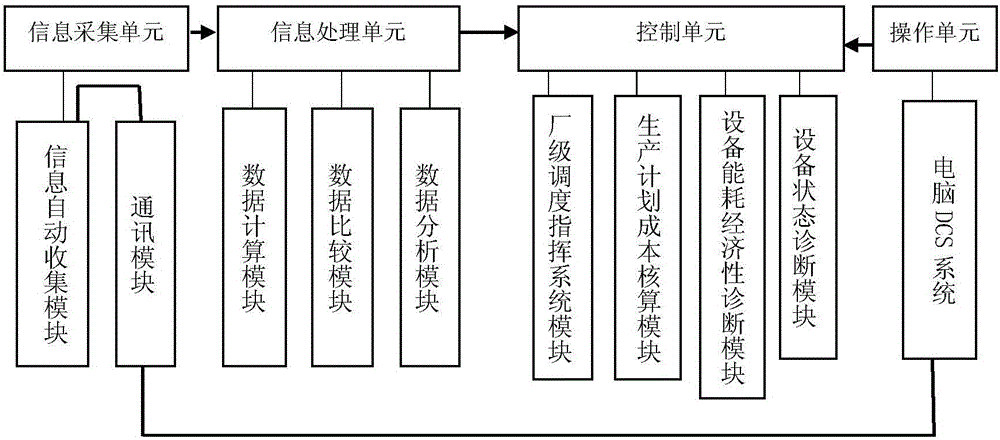

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 Shown: First, the most basic database is provided through the information collection unit, and then the collected data is transmitted to the information processing unit. After the information processing unit processes the data, it will obtain the operating status of the entire system and the status of each machine and equipment. Operation status and work efficiency, and pass this information to the control unit. At this time, the control unit can submit the production task scheduling and allocation plan, submit the production plan plan, perform cost accounting, propose equipment adjustment, Suggestions for maintenance and overhaul, workers operate the operation unit based on these, and various data of the system during and after the operation will be fed back to the information collection unit. For example: when the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com