High-temperature sedimentation stability test device for cement paste

A technology for stability testing and cement slurry, which is applied in the field of devices for measuring the settlement stability of annular cement slurry under high temperature conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

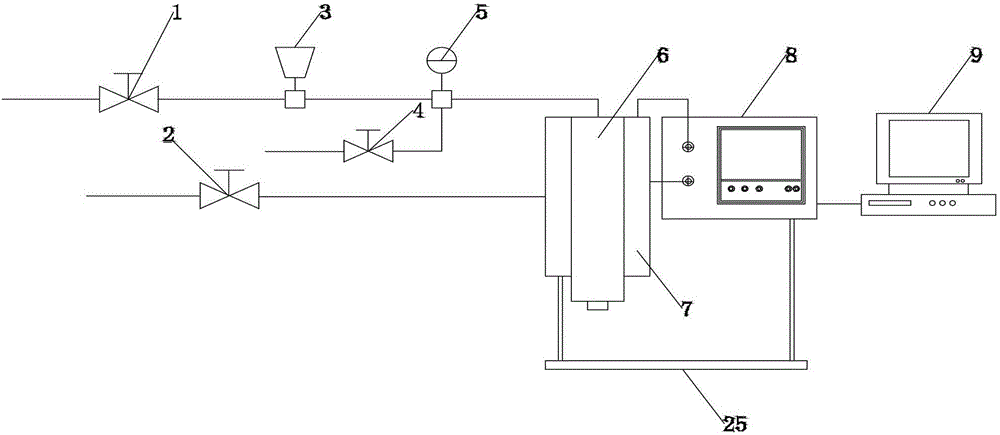

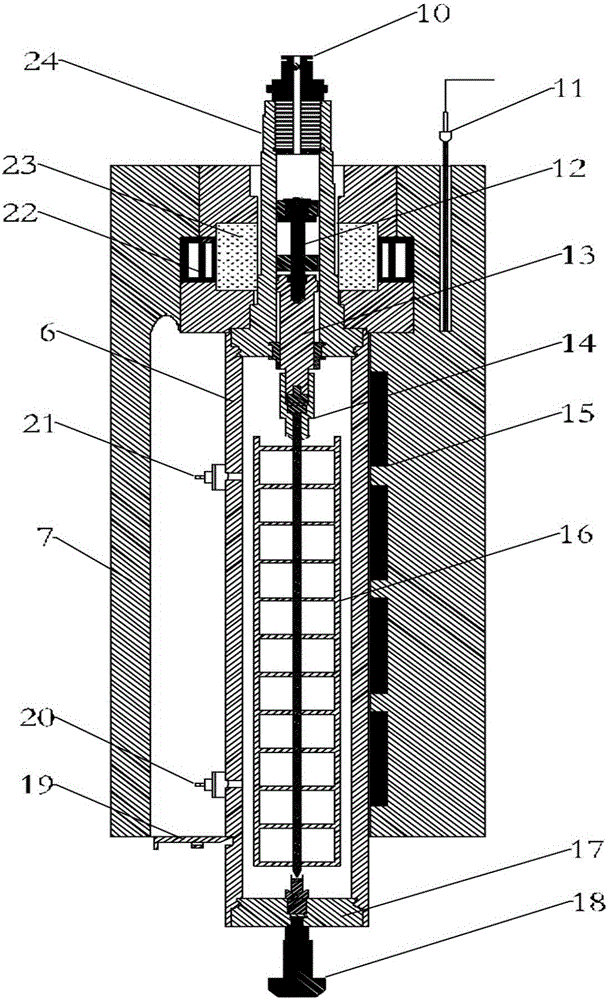

[0040] The test device for the stability of high temperature settlement of cement slurry is mainly composed of base support 25, curing kettle 7, slurry cylinder 6, upper pressure sensor 21, lower pressure sensor 20, temperature sensor 11, control panel 8, computer 9, air source 1 and water source 2. The curing kettle 7 is installed on the base support 25 and can be turned over at any angle. The slurry cylinder 6 is placed in the curing kettle. There is a heater 15 between the slurry cylinder and the curing kettle. The curing kettle body is driven by a pulley 22. The magnet 23 and the temperature sensor 11 are inserted into the curing kettle and connected to the control panel 8 and the computer 9; the upper part of the slurry cylinder 6 is a driving body, and the lower part is a bottom cover 17. The driving body includes a driving body casing 24, a driving body block 10, The inner magnetic rod 12 and the core rod 13, the inner magnetic rod is connected to the core rod, the core r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com