A Triangulation Method for FRP Acoustic Emission Source

An acoustic emission source and triangulation positioning technology, which is applied in the direction of material analysis, analysis materials, instruments, etc., using acoustic emission technology, can solve the problems of acoustic emission propagation speed, positioning error, large acoustic emission wave attenuation, etc., to achieve Ease of operation, accurate measurement results, and the effect of increased sensor spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Aiming at the problem that the traditional acoustic emission non-destructive detection cannot accurately locate the composite material of glass fiber reinforced plastic, the invention provides a triangular positioning method of the fiber glass fiber reinforced plastic acoustic emission source.

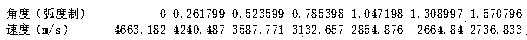

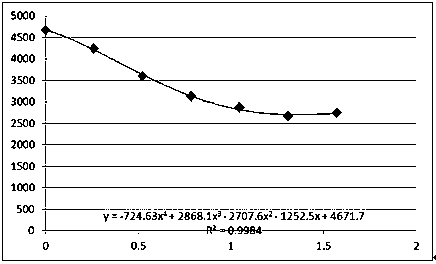

[0037] In step 1, the measurement angle and propagation velocity of the propagation characteristics of the FRP to be tested are measured, and the selected angles are 0°, 15°, 30°, 45°, 60°, 75°, and 90°. The acquired test results were obtained using the curve fitting function in an Excel spreadsheet. The obtained angle-velocity polynomial; the fitting formula contains two variables of angle α and velocity v, such as figure 2

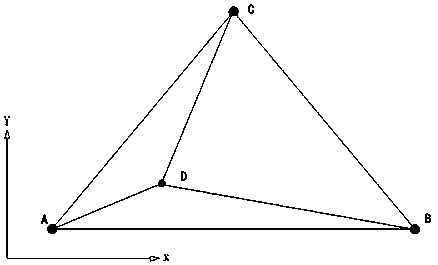

[0038] Step 2, the sensor probe is arranged on the FRP tank body to be tested according to the arrangement method of isosceles triangle;

[0039] Step three, such as figure 1 Set the coordinates A(x) of the three vertices of the isosceles triangle 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com