Measuring method of pulverized coal concentration

A measurement method and pulverized coal technology, which is applied in the direction of measurement devices, neural learning methods, suspension and porous material analysis, etc., can solve problems such as low anti-interference ability, difficulty in realizing real-time online measurement, and small measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

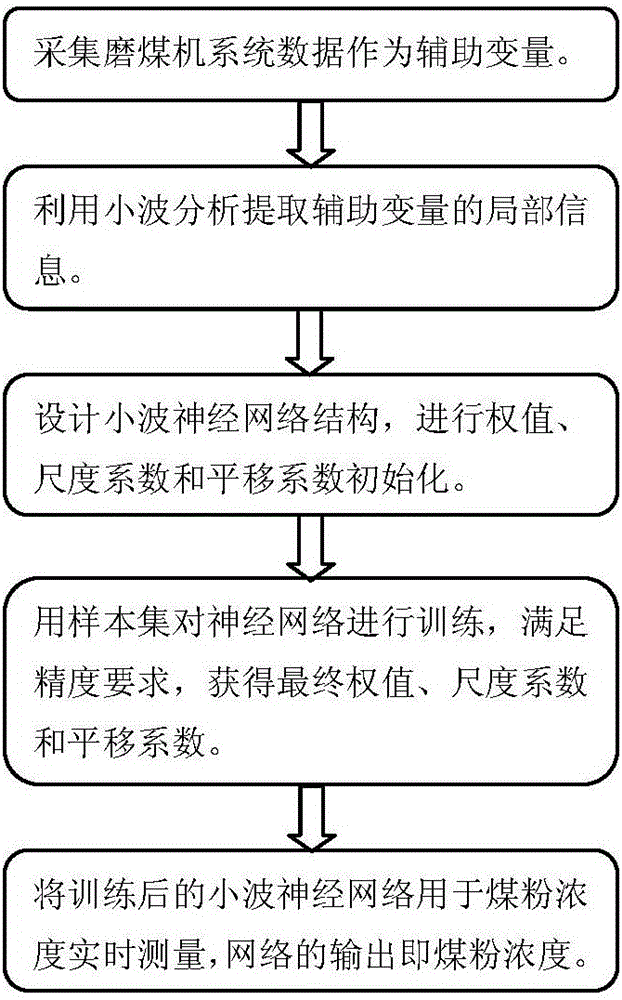

[0056] Below in conjunction with accompanying drawing, the present invention is described in detail:

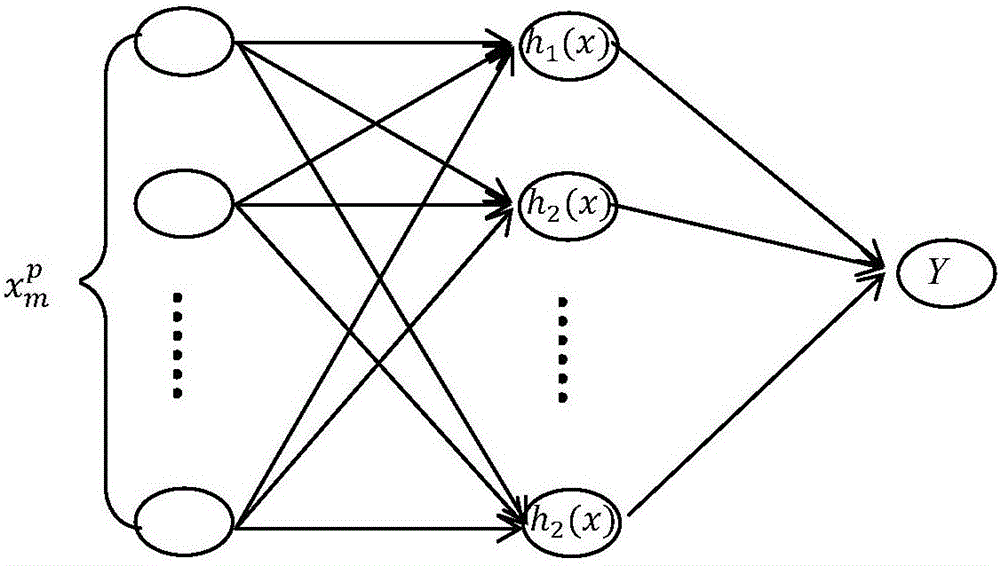

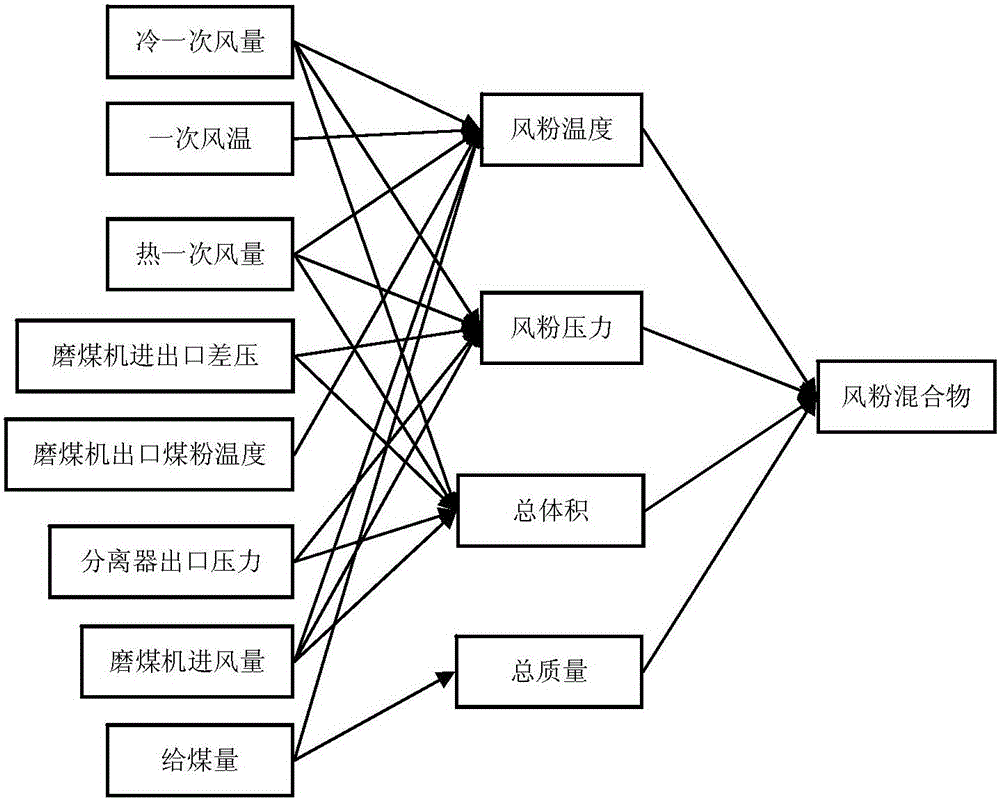

[0057] The present invention utilizes the wavelet neural network to establish a pulverized coal concentration measurement model. The input of the network model adopts auxiliary variables that are relatively easy to measure and are related to the pulverized coal concentration, such as primary cooling air volume, primary air temperature, coal supply volume, primary heating air volume, and coal grinding. The differential pressure at the inlet and outlet of the coal mill, the pulverized coal temperature at the outlet of the coal mill, the outlet pressure of the separator and the total air volume. These auxiliary variables and the measured pulverized coal concentration constitute a nonlinear system, and the initial processing of the input parameters by the wavelet neural network makes the input parameters easier for the learning and memory of the neural network. Use a large number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com