High-temperature superplastic tension large deformation measurement device and method

A measuring device and superplastic technology, applied in the field of instruments, can solve the problems of large deformation error, inability to judge and record the generation and development of necking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

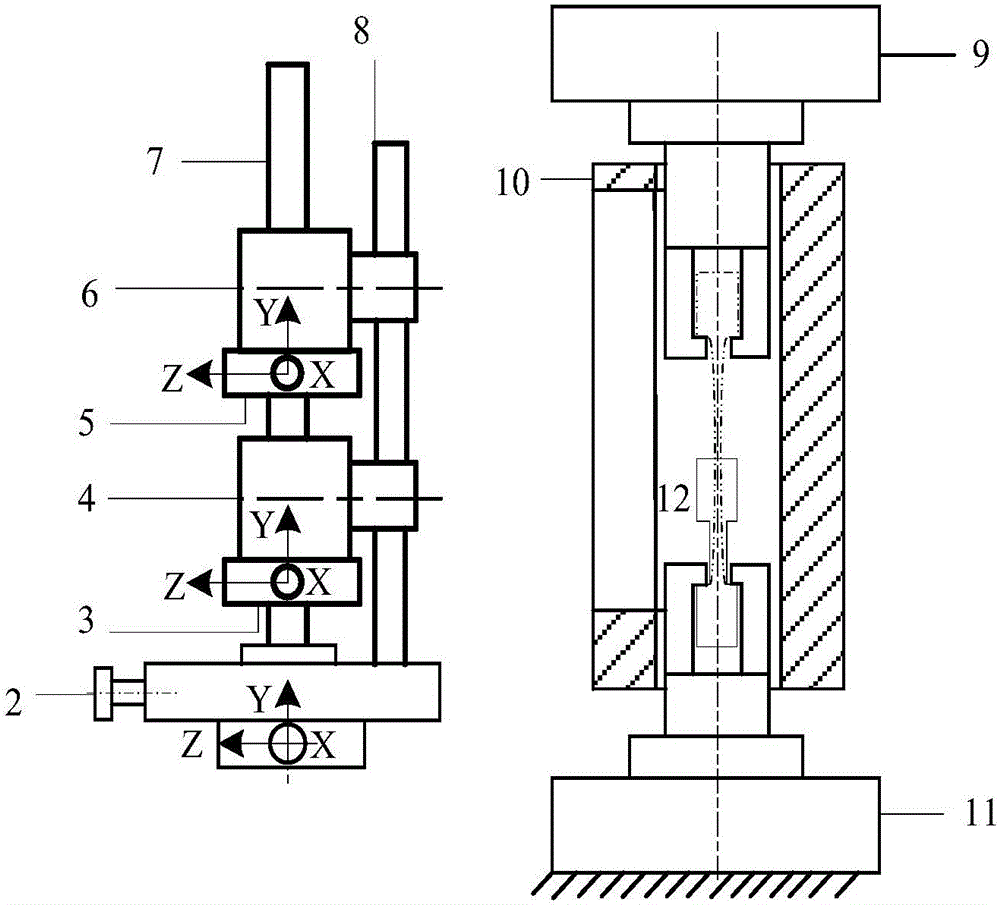

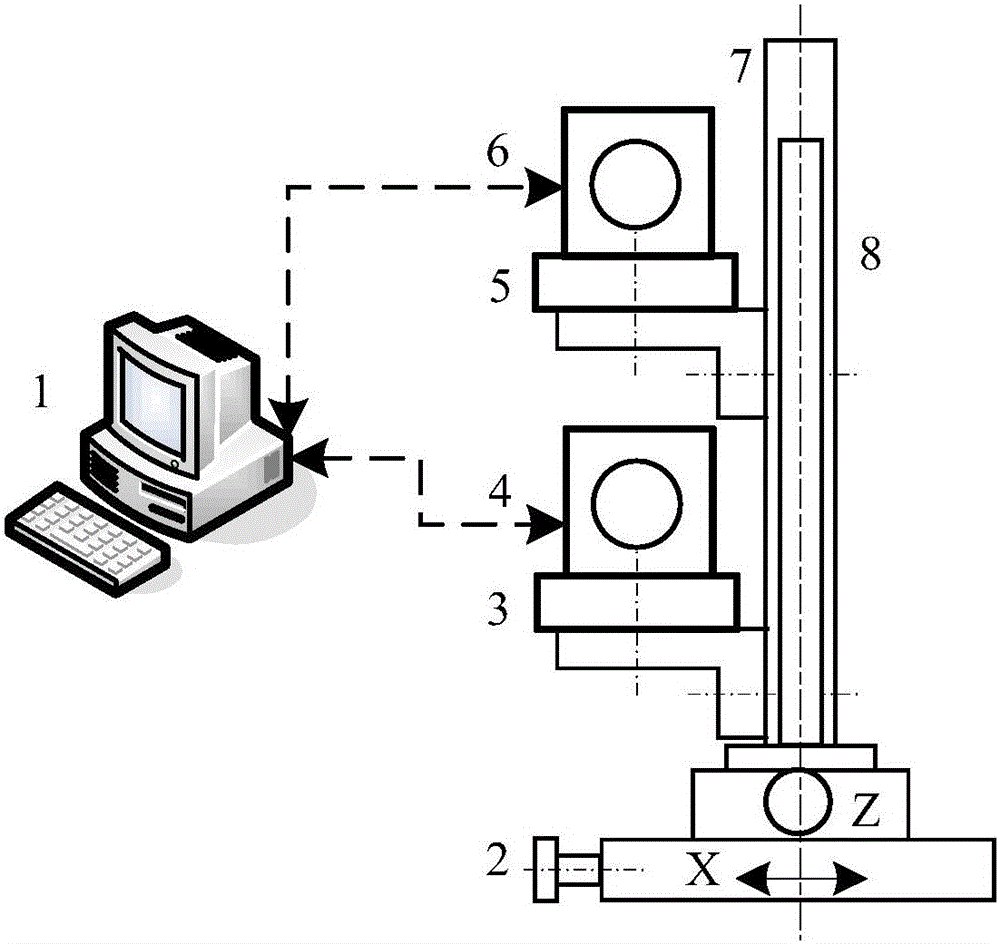

[0077]As shown in Figure 1(a) and Figure 1(b), the high-temperature superplastic tensile large deformation measurement device mainly includes a high-temperature furnace tensile mechanism and a deformation measurement mechanism. The high-temperature furnace tensile mechanism and the deformation measurement mechanism are both vertical Place on the ground.

[0078] The tensile mechanism of the high temperature furnace mainly includes: the lower beam 11 of the testing machine, the movable beam 9, the high temperature furnace 10 and the observation window. The high temperature furnace 10 is a closed furnace body, the lower beam 11 and the movable beam 9 are fixed with tie rods, and the observation window is opened on the side of the high temperature furnace 10 facing the deformation measurement mechanism; the lower beam 11 is fixed horizontally, and the movable beam 9 is controlled by the testing machine. The motor drive can drive the pull rod to reciprocate in the high temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com