Closed-loop steel sintered red ore cooling device and process method thereof

A closed-circuit circulation and cooling device technology, applied in the field of thermodynamics, can solve problems such as belt transportation and ore screening adverse effects, sinter quality cannot be guaranteed, and sintering machine leakage rate is high, so as to reduce power, save electricity, and occupy an area The effect of less area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

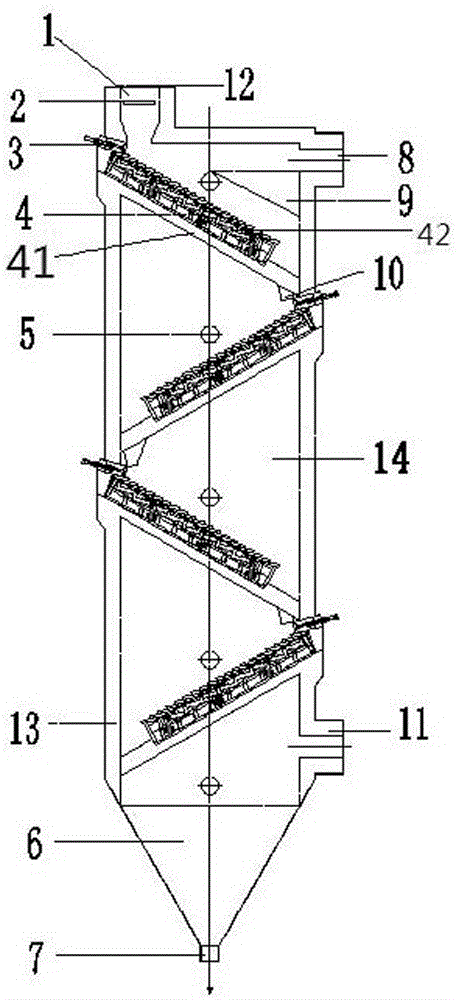

[0031] A closed-circuit circulation iron and steel sintered red ore cooling device, comprising a device body 13, a heat exchange chamber 14 arranged in the device body, a feed inlet 1 arranged at the upper end of the device body 13, and a uniformly distributed Device 2 and the outlet 7 located at the lower end of the body;

[0032] And the cold air outlet 8 provided on the upper end side wall of the device body and the cold air inlet 11 arranged on the lower end side wall of the device body communicated with the heat exchange chamber;

[0033] And the thermostat 9 arranged on the device body, the thermostat 9 communicates with the cold air outlet 8;

[0034] And at least one fire grate 4 that is movably installed in the heat exchange chamber 14, each fire grate 4 is inclined downward with the heat exchange chamber and is arranged in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com